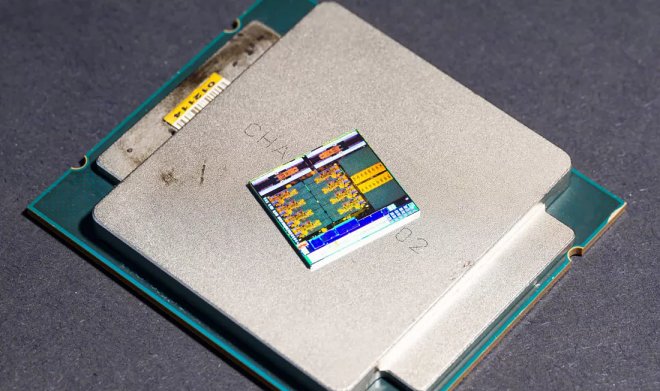

Huawei has patented the production of light conversion for absorption due to interference when operating at extremely short wavelengths. This development makes it possible to use the 10nm process for self-printing microchips. And by doing so, not just to abandon the US sanction, but to challenge the entire industry of data production.

Extreme ultraviolet (EUV) lithography is so complex that the Dutch company ASML took 17 years and more than 6 billion euros of implementation to create a commercial installation for its application. In it, molten tin in America is irradiated with a laser – first to give them the shape of a pancake, and then to. The result is a microcloud plasma that emits EUV light with the required parameters. The process occurs at a frequency of 50,000 per second.

Mirrors in a lithographic machine

Mirrors in a lithographic machineThis technology is extremely secure and available to five companies worldwide: Intel and Micron in the US, Samsung and SK Hynix in South Korea, and TSMC in Taiwan. Other manufacturers, such as Huawei, used to simply order chip fabrication from TSMC, but after the introduction in the US, this option became unavailable. It is possible to repeat the case of the formation that the necessary eu-sensation balances on the f and r r f

However, Huawei engineers added the following results, at first the system was cut off from the interfaces. The initial beam is divided into “sub-beams”, which are transmitted to microscopic mirrors with individual parameters. This allows one to adjust the interference effects for their mutual neutralization and, as a result, to add all the “sub-beams” in accordance with the beams required for EUV lithography. .

Source: Tech Cult