Our favorite Apple smartphone is manufactured not in one, not even in ten different factories. Dozens of companies around the world participate in the creation of a complex gadget.

Which Countries Really Make iPhones

We decided to collect statistics on the production of components and assembly of the iPhone to understand how the iPhone was made 10 years ago and what has changed during this time.

Where iPhone components were designed and manufactured 10 years ago

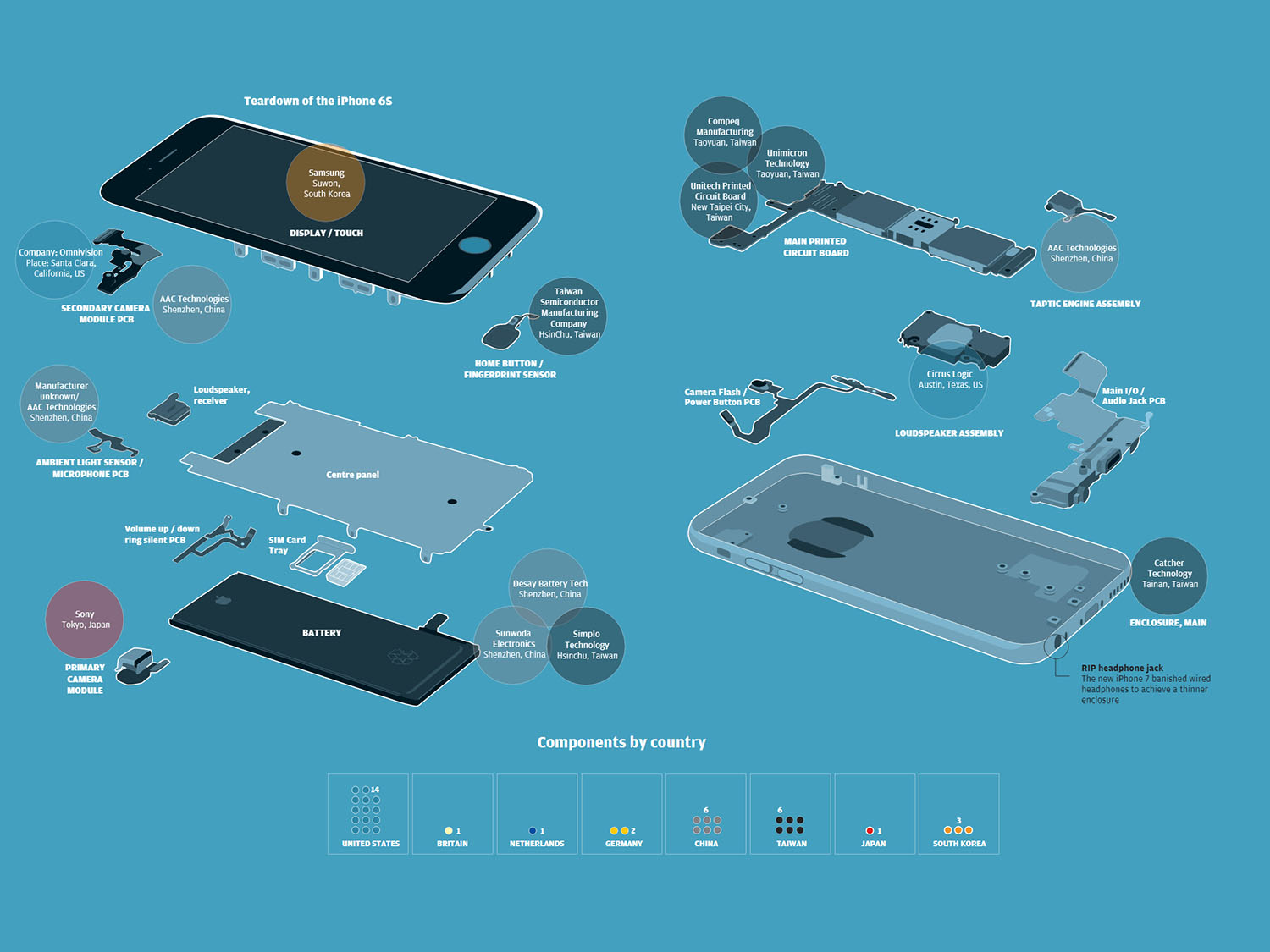

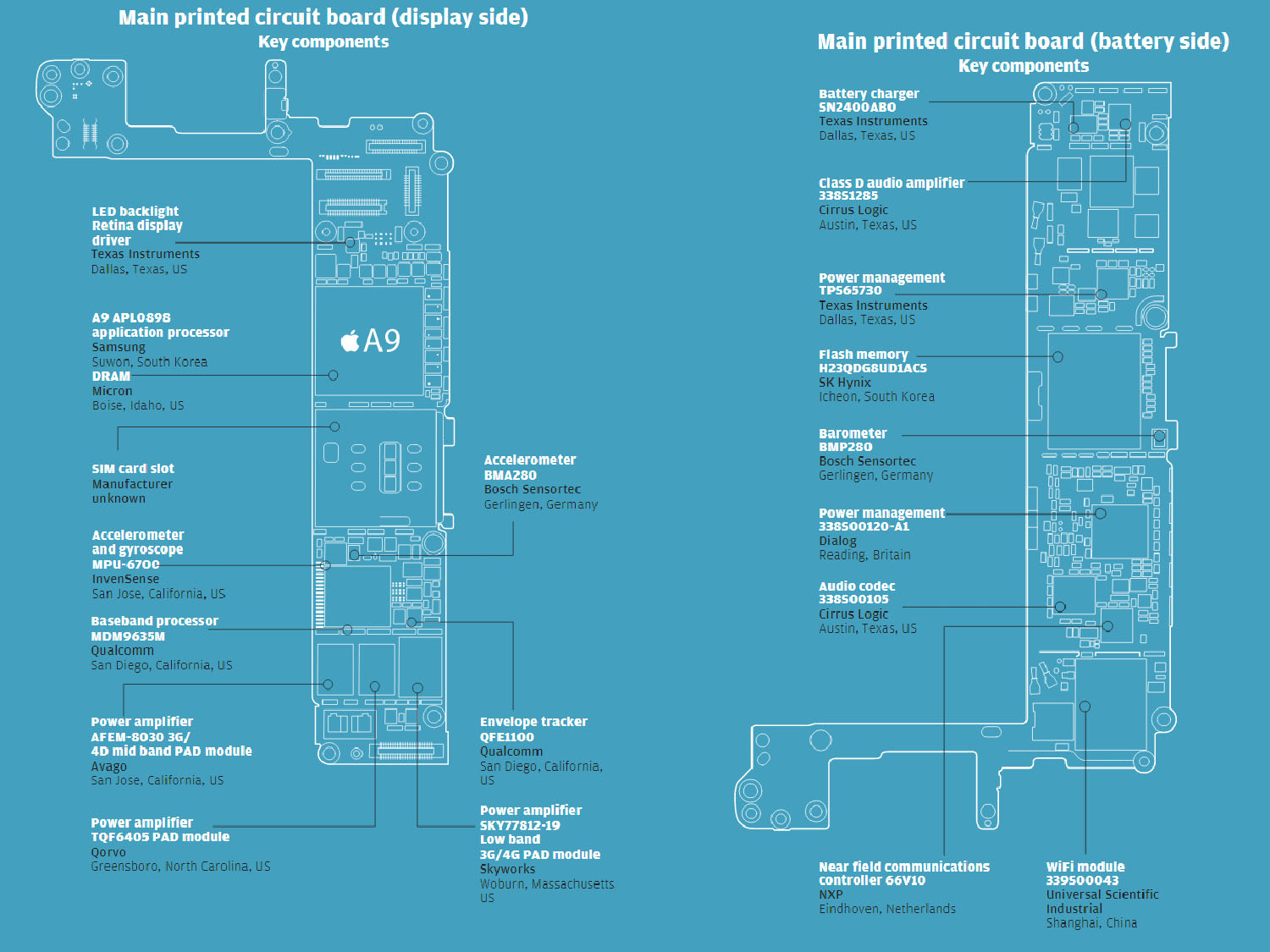

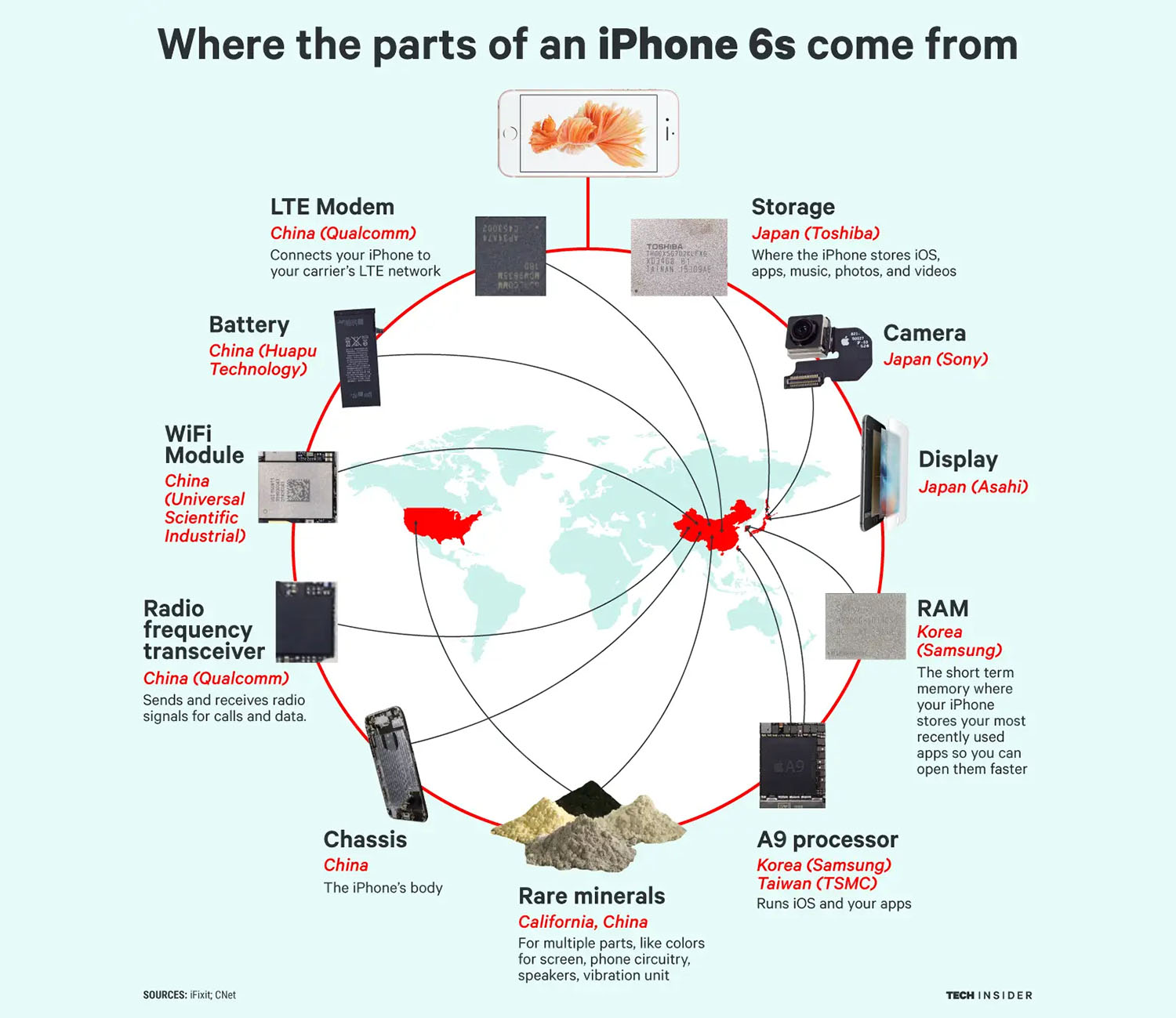

In times iPhone 6/6s The situation was very different. Even then, the smartphone was a mobile phone technology. Companies from 8 countries participated in the development of Apple smartphones, and the total production was only in 3 of them.

The following countries were involved in the development of components:

🇺🇸 USA14 components: the motherboard and most of the modules on it.

🇨🇳 China6 components: battery, Wi-Fi module and a number of other parts.

🇹🇼 Taiwan6 components: Touch ID, housing, printed circuit boards

🇰🇷 Top down.3 components: LED, processor and RAM

🇩🇪 Germany2 components: accelerometer and barometer

🇬🇧 Britannia1 component: power controller

🇳🇱 Netherlands1 component: NFC

🇯🇵 Japan1 component: camera module

The following companies were involved in the production of iPhone components:

🇨🇳 China: battery, GSM and Wi-Fi modules, case

🇰🇷 Top down.: RAM and processors

🇯🇵 Japan: cameras, storage devices and displays.

Only Asian countries can master such high-tech production at an affordable price.

Assembling an iPhone bag only in Chinese at the factories of Apple’s main partner, the company Foxconn.

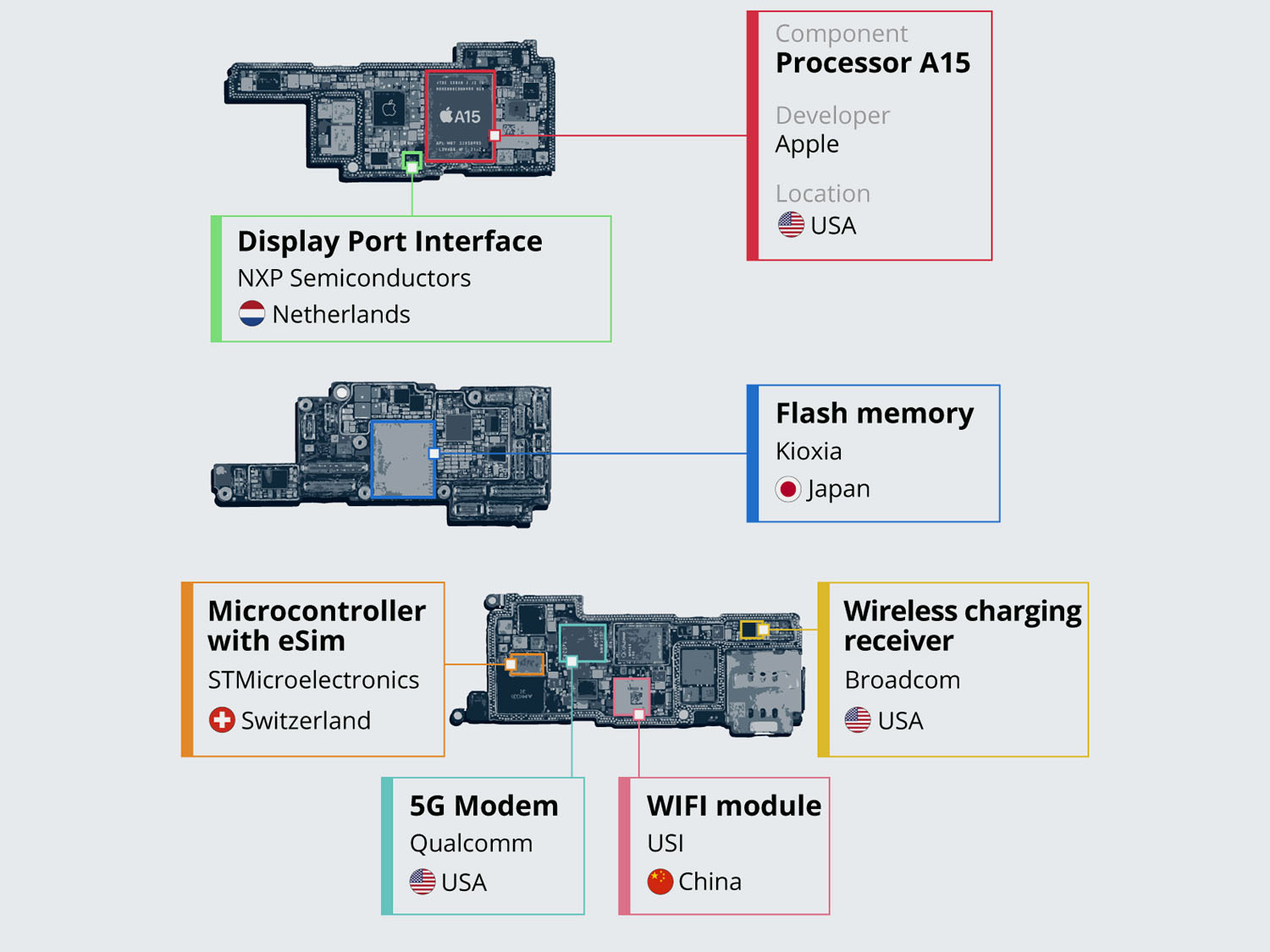

Where iPhone components are currently being developed

In recent years, Apple smartphones have become even more technologically advanced, they have new components and modules, and the geography of production has greatly expanded.

🇨🇭 Swiss to develop a gyroscope and an eSIM module

🇩🇪 In Germany Accelerometer development has been developed

🇬🇧 In United Kingdom Developing audio chips

Apple has several partners with offices in dozens of countries around the world. And it turns out to be very difficult to find out where exactly the screen glass, the display itself, or the flash memory is made — each model, even within the same iPhone line, can have components from completely different countries, with the exception of the processor and the motherboard.

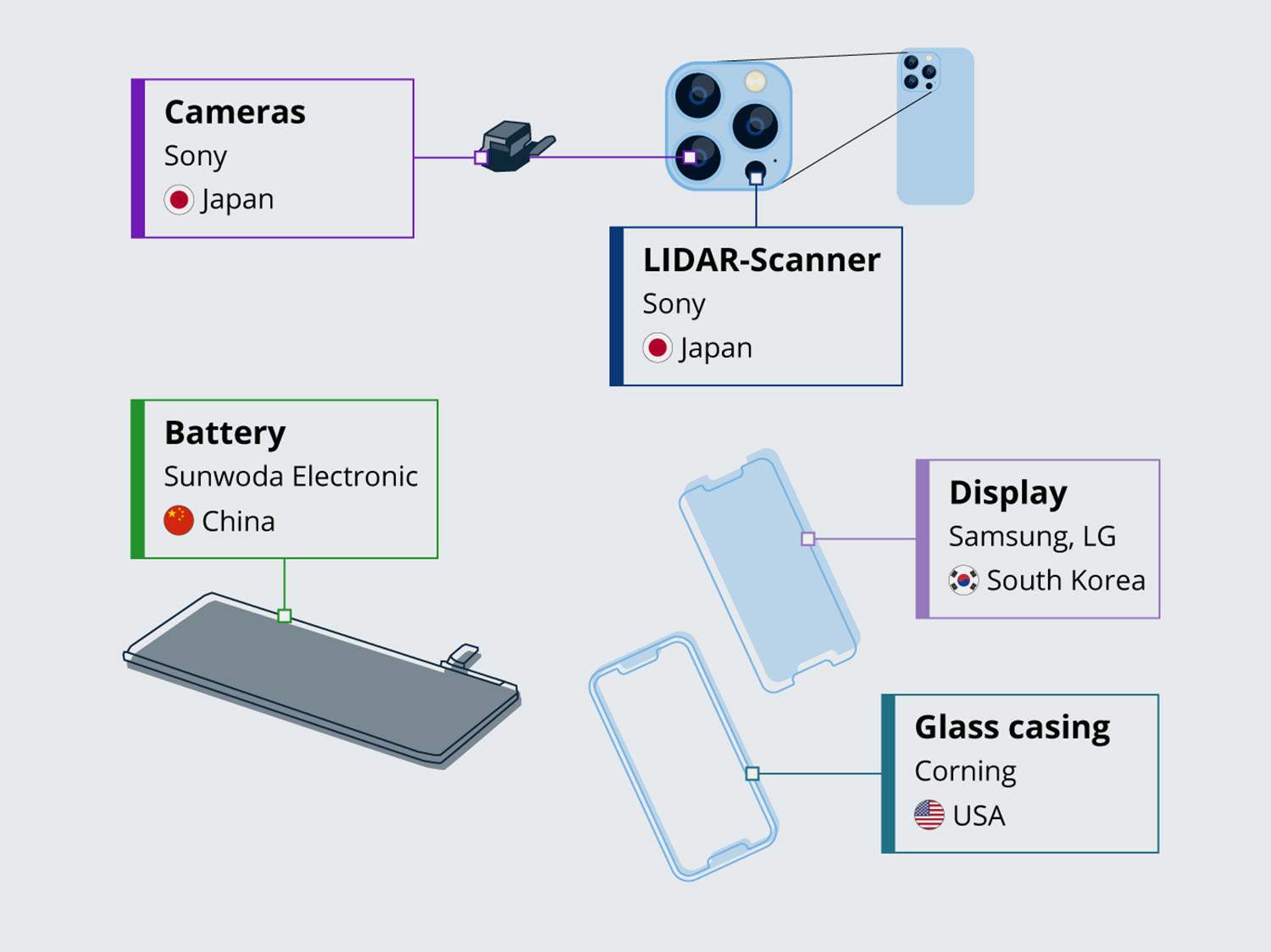

Where iPhone components are made today

If previously production was concentrated in three countries, now the Cupertino company is slowly expanding the geography of its countries – mainly in Southeast Asia.

🇨🇳 ChinaAs before, it produces most of the elements of modern iPhones, which is up to 60% of all electronics on the devices.

🇯🇵 Japan is responsible for the production of displays and cameras

🇰🇷 Top down. produces RAM, processors and memory

In addition, the components are made in factories in Taiwan, Thailand, Vietnam, Philippines, Malaysia And Indonesia.

Where iPhones are assembled now

🇨🇳 As before, the main assembly lines were located at Foxconn factories in Chinese. According to statistics, at the peak of production, an Apple partner can assemble about 500 thousand iPhones in one day! However, the situation is gradually changing.

The COVID-19 pandemic (remember that?), the rapid war between the US and China, and the semiconductor crisis have forced Apple to “not keep all its eggs in one basket” and diversify its hardware supply chain.

🇮🇳 Starting from iPhone 12Apple assembles some models on site India. The Pro and Pro Max versions are not yet manufactured here. Currently, approximately every 7th iPhone is manufactured in India. In this country, 2-year-old Cupertino-based phones account for up to 25% of iPhones in the country (every 4th).

🇻🇳 Soon iPhone will start to be assembled in Vietnam. It now produces nearly 65% of AirPods, 20% of iPads and Apple Watches, and 5% of MacBooks sold worldwide.

About the transfer production There is no talk of other countries yet, but there are rumors that the company has been looking for partners for this complex task for two years now.

What’s the bottom line?

The iPhone is a complex product made up of equally complex and technologically advanced components. It is virtually impossible to develop, study and assemble them into a finished device in one country.

Currently, more than 20 companies from a dozen countries are responsible for creating components. The main development is carried out in USAand in other countries we are engaged in the creation of individual modules.

Assemble parts and modules in Chinese, Japan, South Korea and other countries Southeast Asia.

Until recently, smartphone assembly took place only in Chineseand now it is done in Indiaand soon – in Vietnam.

The main thing is that Apple is a dynamically developing corporation that is holding on to the wind and reacting to external factors, trade wars and pandemics. The Cupertino company is constantly looking for more favorable conditions and new partners. I can say with confidence where the iPhone will be assembled in another 10 years, no one will be able to.

Source: Iphones RU

I am a professional journalist and content creator with extensive experience writing for news websites. I currently work as an author at Gadget Onus, where I specialize in covering hot news topics. My written pieces have been published on some of the biggest media outlets around the world, including The Guardian and BBC News.