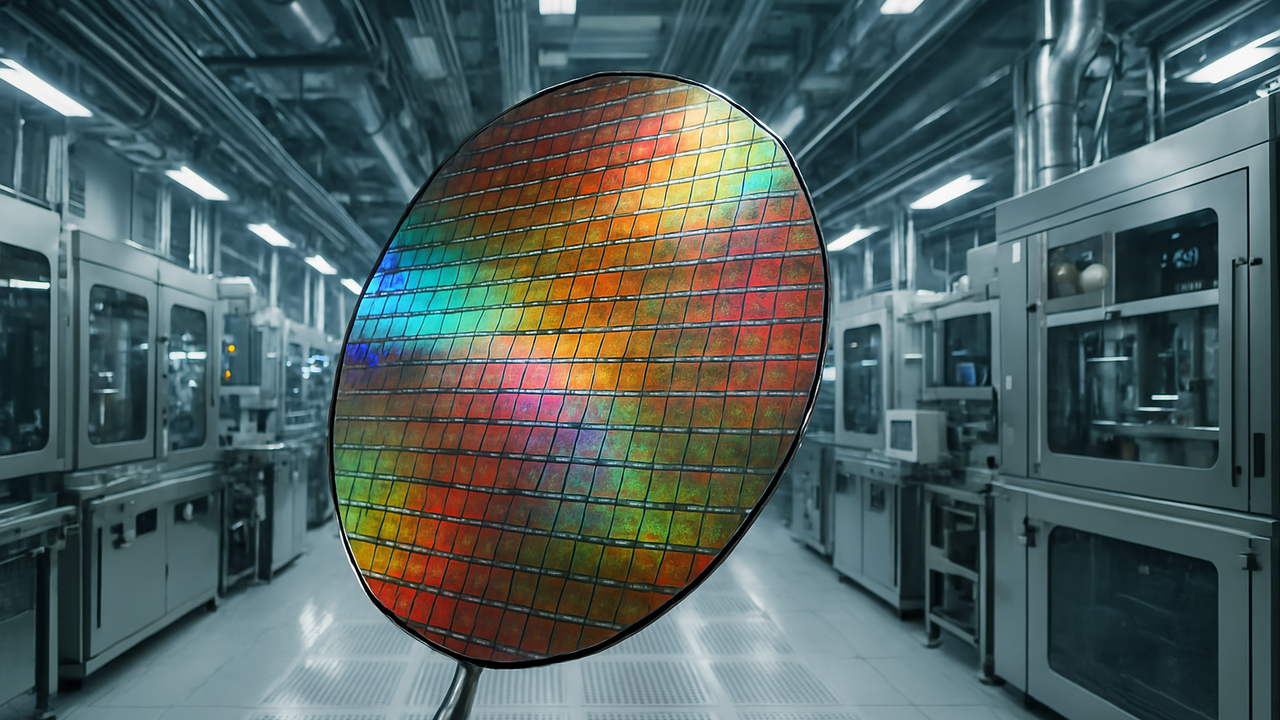

This will be the first step towards full -scale production of chips until 2027. The company plans to complete its first test plates by July and then offer PDK sets for prototyping customers.

In the factory in Hokkaido, advanced lithographic equipment from ASML, including EUV and veil systems, was already established. Similar to TSMC and Samsung Technologies, Rapidus uses the architecture of the transistors of the Al-Al-Air Tip.

The main difference will be the automatic packaging of chips instead of production – none of the competitors offer it.

So far, Rapidus focuses on the release of plates and the packaging work will be held at the new RCS (Rapidus Chiplet Solution) next to the main facility.

This is Japan’s largest technological project in recent years, which aims to reduce dependence on TSMC and Samsung in the production of advanced chips.

Source: Ferra

I am a professional journalist and content creator with extensive experience writing for news websites. I currently work as an author at Gadget Onus, where I specialize in covering hot news topics. My written pieces have been published on some of the biggest media outlets around the world, including The Guardian and BBC News.