As is well known, there are two problems in Russia: fools and roads. The first problem is a subjective question, stupid people live not only in Russia. Moreover, our domestic ingenuity is a source of pride for us. But what is wrong with the roads? Yes, we can point to the harsh climate, according to some historical patterns, but this does not change the indisputable fact of our lagging behind in this matter.

Bad roads mean slower travel speeds, premature wear and tear on vehicles, and they also have an impact on accidents. It is known that 20 to 40% of road accidents are caused by bad roads. So their condition is important, without exaggeration, state task. The economy of a successful country is supported by quality roads.

Briefly

Which country has the best roads

How Americans Began Building Their Roads

Road Construction Technology in America

Concrete roads in Russia

How Roads Were Built in Russia

Why turn the wheel?

Why our roads are worse than Scandinavian ones

What is the problem with Russian roads?

Which country has the best roads

American highways are the country’s circulatory system

Roads are not only highways, they also connect rural areas. But to assess the quality of the road transport network, the average speed between cities is usually taken. However, there is usually a direct correspondence between the quality of main and secondary roads.

The United States, as expected, came first in this rating with an average speed of 107 km/h. The top twenty countries include successful Canada, France, the Czech Republic, Germany and Sweden, as well as the unexpected South Africa, Namibia, Morocco and Iran. Russia did not make the list of leaders.

How did Americans start building their roads?

Cars have appeared, but roads have not yet appeared!

Let’s debunk the myth: roads in America cannot be named. First of all, because roads can be different. One thing is the famous highways that cross entire states interstateanother matter is rural and urban roads. However, no less distinctive feature of highways in America is their average quality. Road surface is more or less good everywhere, and not only around large cities. And there is a historical explanation for this.

When Henry Ford put America on wheels, it turned out that the country had neither proper roads nor the technology to build them. Workers threw crushed stone onto a somehow prepared surface, and then a roller drove over it. Cars were even sent to the intervention of the government of their country!

From 1901 to 1938, the length of roads increased from 1,200 km to 448 thousand km! Based on the concepts of German autobahns, in 1956 the USA adopted the standards for motorways that are still in force today. They provide for accessibility for different types of transport, width, number of lanes, etc. By 2018, the total length of roads was more than 7 million km, with almost 78 thousand km being high-quality motorways.

Road Construction Technology in America

Reinforcement is an important part of a concrete road

In America, road construction requirements took into account the requirements of the Department of Transportation. At the same time, these standards are mandatory for all states, which makes the quality of roads more or less the same throughout the country.

And what makes roads so high-quality is concrete. Its use is the very guarantee of quality. Concrete has bright advantages: strength, durability, load-bearing capacity. Disadvantages include the complexity of laying and subsequent repair. The first road made of this material appeared in the country back in 1930, although roads began to be made even earlier.

The oldest concrete street in America

The construction of the road begins with digging a hole of a depth, and the rock is used later for the embankment. Then a cushion of gravel, sand and clay is placed on the bottom. Each layer is polished with a known solution and plowed. Since the room allows water to be kept inside, it remains in the cushion and does not allow it to sag over time. A 5-7-centimeter layer of asphalt is placed on top. It provides a smooth surface and waterproofing.

The next step is installing the reinforcement. Concrete is poured onto it and then compacted, forcing the air out of it. The air temperature is also taken into account – in hot states, concrete is laid at night so that the mixture loses less moisture. It can also be watered or even wrapped in film.

Building a concrete road in America is routine

Pay special attention to quality materials and work. Moreover, back in the 60s, Americans described the properties of different crushed stones, and when pouring each section, concrete cylinders oscillated. They are then broken, checking the quality of the material in accordance with building codes.

Concrete hardens in 28 days. But such a road can serve up to 25 years without major repairs. But after the concrete wears out, it can be covered with asphalt on top – this way you can prolong the life of the road for a while and postpone repair work. The technology is not cheap, but further operation is relatively inexpensive.

Concrete roads in Russia

In Russia there are also concrete roads, but they are only no more than 3%, while in America it is ⅔. Our options are either some bold experiments or simply rebuilt runways. This situation is explained by several factors.

The concrete road itself will obviously be more expensive than a regular asphalt road, almost 4 times more, even if it pays off faster. And maintenance is another story, which “feeds” too many interested parties. A road that does not need repairs for 20 years? Sounds tempting for motorists, but for someone it is a shock!

It is also worth mentioning that the construction of a concrete road requires special cement. We do not produce enough of it to use it in this area. Yes, and special construction equipment is required for laying concrete, someone will have to invest in this too.

The concrete paver looks solid

But there is another, perhaps the most important, reason. The advantage of concrete is its resistance to heat. This is relevant for the southern United States and China. But in reality, we often encounter sharp temperature changes. And it is in such conditions that cracks can occur. Asphalt also does not always withstand such changes, but at least it would be easier to repair.

Operation of a concrete road is a special story. Pothole repairs are not enough here. A whole section of the road is replaced so that the problem does not spread. Not only is this very expensive, but you also have to wait for the concrete to dry, and this takes several days. In winter, special reagents are needed, and how concrete tolerates the long-term impact of spikes is a mystery.

How are roads built in Russia?

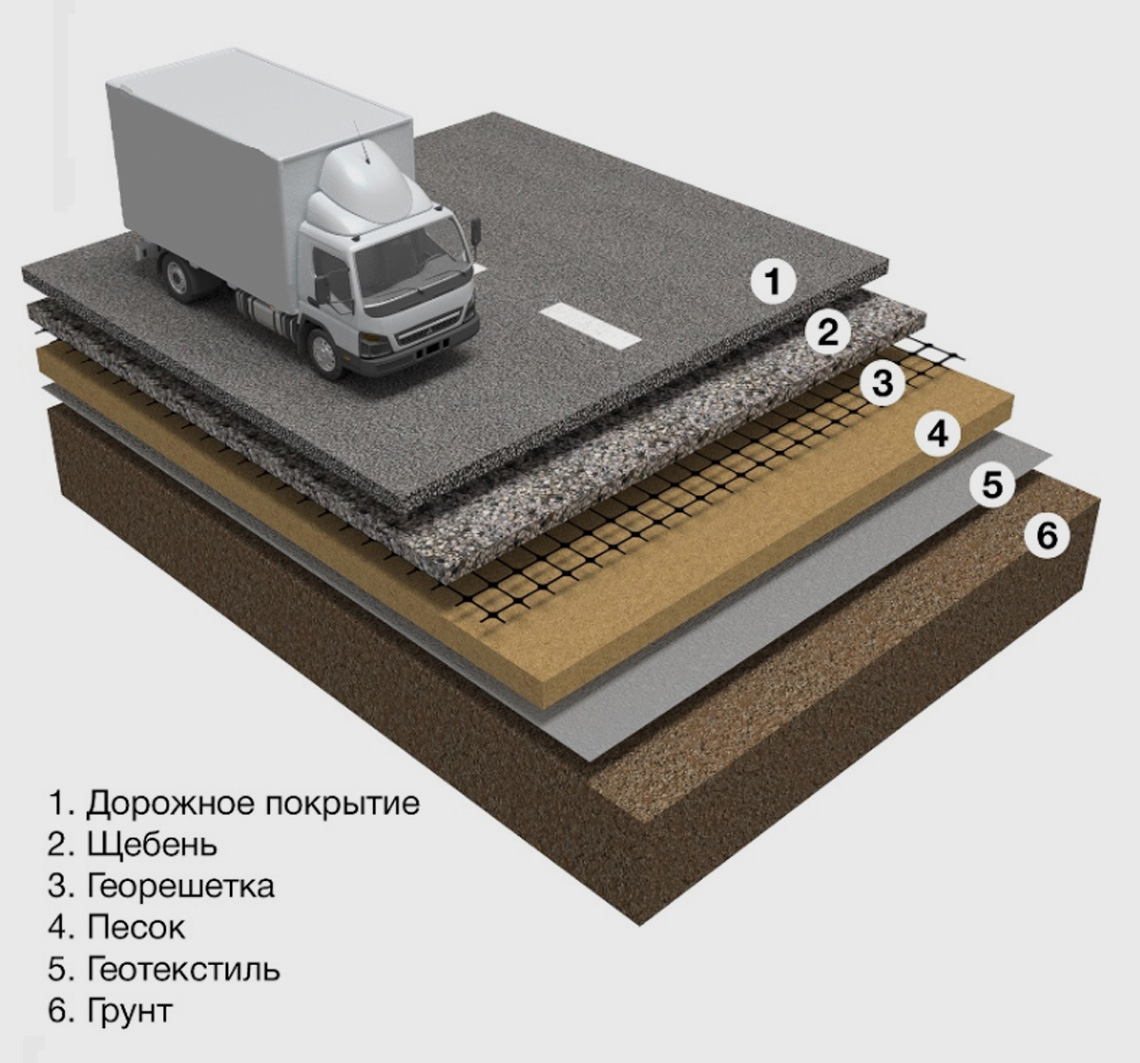

A variant of the road “pie”

Domestic roads are also a layered pie, whose thickness and composition depend on the purpose of the transport facility. The women’s construction process is regulated by the Urban Development Code, the main GOSTs and SNiPs.

Geotextile is placed between the first layers of natural soil, sand and crushed stone. The underlay prevents the layers from mixing and removes excess moisture. Crushed stone due to its resistance to high temperatures. This layer is impregnated with bitumen to improve density and viscosity, as well as for better fastening with the asphalt concrete layer.

On the best, first category roads, concrete 20–35 cm thick is laid as a base, and then layers of asphalt are laid on top: from coarse-grained to fine-grained. Asphalt laid directly on crushed stone is a technology from the Soviet Union, now it is used for the lowest category roads.

Of course, forming such a “pie” is a whole science. Thermal incompatibility of materials can lead to cracks in the cement concrete itself and above. And cheap crushed stone can unevenly settle under the influence of transport load, which will lead to the viewer and the track.

Road construction could be a large-scale project

Hot asphalt can only be laid in warm and dry weather at a temperature of 5 degrees. The asphalt paver plays an important role at the last stage. The roller compacts the site, and it is the roller that makes the road so smooth. The equipment is constantly being improved, vibratory rollers have already appeared, which have an additional effect on the asphalt, helping it to be even denser, etc.

Why build a wheel?

Potholes are not the only problem with our roads. Even if the asphalt surface seems to be intact, it may still be subject to deformation known as rutting. This is the name given to a noticeable change in the cross-section of the road, which is created in the lanes where cars most often drive. The rut can become so obvious that it greatly impedes the movement of cars, especially those with low ground clearance. Changes can affect not only the top layer, but also the inner layers.

The track clearly hinders movement

The main reasons for the appearance of ruts on the road are known:

📍 Poor quality asphaltThe surface softens under the influence of the sun, and then it is simply crushed by the wheels of heavy vehicles.

📍 Thin layer of asphalt and road cushion. Mistakes made in the project or during installation will accelerate the emergence of problems.

📍 Increased traffic loadEven at a qualitative level of design profitability, a rut may appear if the load significantly exceeds the initially profitable one.

Was the road really designed for the charge coat?

📍 Studded tiresIn our conditions, such rubber can be on cars for most of the year, negatively affecting the asphalt.

📍 Poor road maintenance. Even repairs carried out at the wrong time cannot stop the rut from appearing. As a result, all layers of the road surface will have to be replaced.

But there are also other, less obvious reasons: fatigue stress in the road layers, chemical effects, soil subsidence, expansion of groundwater, etc.

Why are our roads worse than Scandinavian ones?

Problems with Russian roads can be largely explained by the climate. But why then are Scandinavian countries with equally harsh conditions generally better? And here we should not blame corruption or the use of independent technologies. These factors also show, but they are far from the main ones.

It looks futuristic, but deserted, and there are only two lanes.

Roads in Northern Europe are not as loaded as ours, therefore, they initially serve longer. There are also more toll sections, which allows collecting additional funds for maintenance and repair. And the roads themselves are much more modest: in Norway, for example, they are mostly two-lane, although bridges and tunnels are separate stories. Longer and shorter lengths of roads in Scandinavia.

What is the problem with Russian roads?

Even in the provinces there are normal roads – not everything is so bad!

It seems that one could easily write a whole research paper about the state of Russian roads, the reasons for this phenomenon, and possible solutions. One could talk about a whole range of reasons. Geography makes our roads very long, the climate does not allow for the active use of concrete pavement, and the state of the budget requires savings on technology and subsequent repairs, which only exacerbates the problem.

Russia also has great roads, which were built with all the necessary technologies, and their condition is monitored. How much it cost is another question. So, specialists, materials and technologies are available. It seems that our road problem will not be solved quickly, but children are not a secret for this action.

Source: Iphones RU

I am a professional journalist and content creator with extensive experience writing for news websites. I currently work as an author at Gadget Onus, where I specialize in covering hot news topics. My written pieces have been published on some of the biggest media outlets around the world, including The Guardian and BBC News.