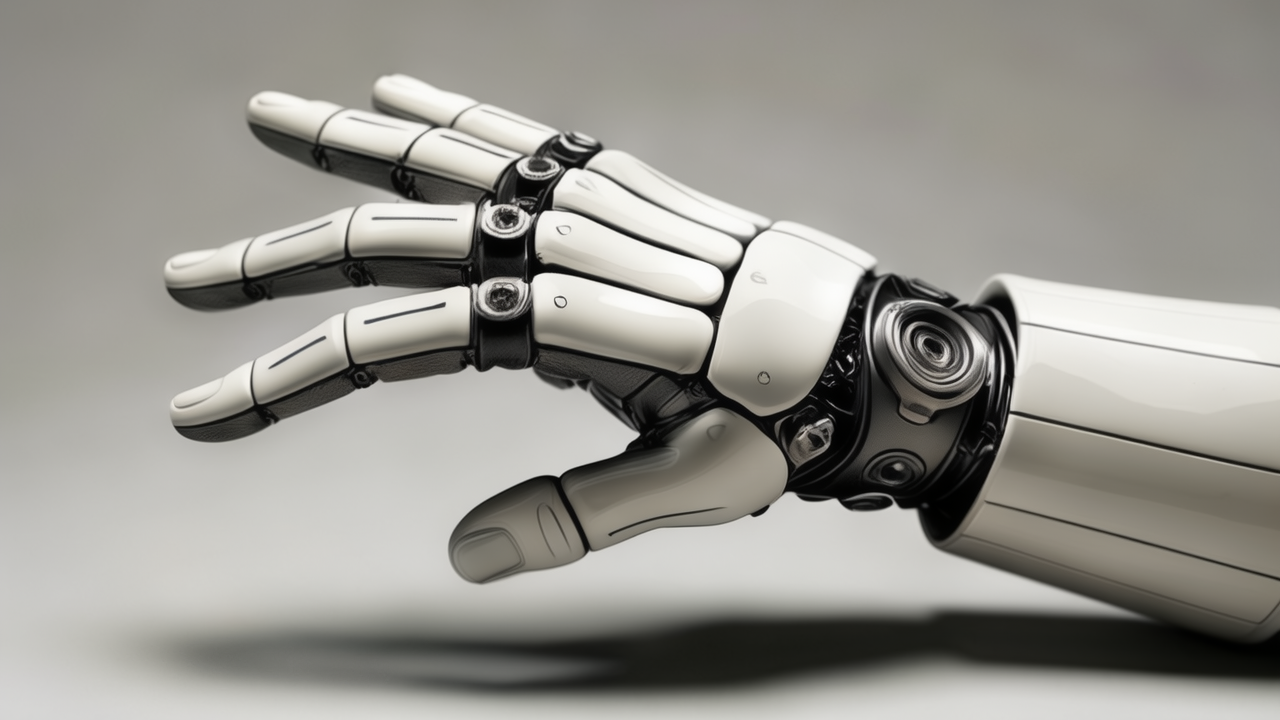

The state agency noted that the project was developed using the latest prosthetic technologies and original design. A special relief on the inner surface of the nozzle provides reliable holding of objects without the risk of slipping. The “gripper” is made of corrosion-resistant steel and is more durable compared to foreign analogues such as Ottobock products.

In the first phase, the prosthetics were made using 3D printing and then switched to lost wax casting, reaching a product weight of 300 grams. Mass production has already begun.

Source: Ferra

I am a professional journalist and content creator with extensive experience writing for news websites. I currently work as an author at Gadget Onus, where I specialize in covering hot news topics. My written pieces have been published on some of the biggest media outlets around the world, including The Guardian and BBC News.