For many, flying on an airplane seems like a boring journey of time. You sit in your seat, eat, read or sleep, and then you go out thousands of kilometers to some other country.

We don’t think about how exactly the plane takes us from one point to another, and it’s a shame. The reason for the devices was the monotonous hum that was heard throughout the flight, which is worthy of a separate story.

Starting with the fact that these engines were invented in our country, ending with the principle of their operation point by point – read below. You will know yourself and tell your children about what happened.

Briefly

Who invented the passenger plane engine?

The most popular aircraft of our time

How an Aircraft Engine Works

How much fuel does a modern aircraft engine need?

How passenger aircraft engines are tested

Who invented the passenger plane engine?

Arkhip Mikhailovich Lyulka was an outstanding Soviet scientist and designer, a specialist in the field of aircraft engines.

Arkhip Mikhailovich Lyulka was an outstanding Soviet scientist and designer, a specialist in the field of aircraft engines.

All modern aviation is based on the work of the turbojet engine. But in order not to overload you with terminology in the future, I will call it either an Aviation Engine or an AD.

Did you know that the first prototype of an aircraft engine for passenger planes was created by a Soviet engineer?

Turbojet engine AL-7F. The heart of Soviet aviation.

Turbojet engine AL-7F. The heart of Soviet aviation.

Arkhip Lyulka, an outstanding Soviet designer, is rightfully considered the “father” of modern engines for transport and passenger aircraft. In 1941, he received a patent for the invention of a unique turbojet twin-circuit engine.

However, due to the outbreak of the Great Patriotic War, he was unable to bring his idea to life and build a prototype of the installation.

The Il-62 is the first Soviet long-range first-class passenger aircraft designed for intercontinental flights. It was developed under the supervision of Sergei Vladimirovich Ilyushin and equipped with an aircraft engine created under a patent by Arkhip Lyulka.

The Il-62 is the first Soviet long-range first-class passenger aircraft designed for intercontinental flights. It was developed under the supervision of Sergei Vladimirovich Ilyushin and equipped with an aircraft engine created under a patent by Arkhip Lyulka.

He returned to the project only in 1947. Under the leadership of Arkhip Mikhailovich, the first Soviet aircraft engine (AD) for passenger and cargo aviation was created that same year.

This device has successfully passed tests and has been launched into production.

◦ Back to Contents ◬

The most popular aircraft of our time

So, we have learned who was at the origins of the creation of modern aircraft engines. Now let’s look at the most original types of modern engines based on the most famous aircraft in the world.

The Boeing 737 MAX is an airplane that can carry up to 186 passengers up to 6,500 kilometers.

The Boeing 737 MAX is an airplane that can carry up to 186 passengers up to 6,500 kilometers.

📍 Boeing 737 MAX — one of the most popular aircraft in the history of aviation, on par with Airbus airliners. It was released in 2010 and is equipped with two CFM International LEAP-1B engines. These engines are aimed at the efficiency and reliability of the aircraft.

Thanks to the use of CFM International LEAP-1B, the aircraft’s maximum speed is 910 km/h, and its cruising speed is 835 km/h.

Thanks to the use of CFM International LEAP-1B, the aircraft’s maximum speed is 910 km/h, and its cruising speed is 835 km/h.

📍 Tu-204/214 — is a medium-range, narrow-body passenger aircraft developed in the late 80s – early 90s at the Tupolev design bureau.

Unlike its predecessor, the Tu-214 has increased efficiency, comfort and a high level of safety.

It was created to replace the Tu-154 on airlines and can carry up to 210 passengers over a distance of up to 4,500 kilometers. Aircraft of this model are equipped with modern PS-90A engines.

The PS-90A has a high compression ratio, which allows it to operate effectively at high altitudes and speeds. This engine is the most reliable and popular in Russia.

The PS-90A has a high compression ratio, which allows it to operate effectively at high altitudes and speeds. This engine is the most reliable and popular in Russia.

At present, there are 12 modifications and configuration options for this aircraft.

Among them is the Tu-204-300 “Salon” – a modification developed for the internal affairs of the Russian Federation.

◦ Back to Contents ◬

How an Aircraft Engine Works

Aircraft engine on a Boeing 777-300.

By the way, the phrase “flaming engine” in “March of the Aviators” is not just a beautiful metaphor. Inside the aircraft engine, there really is a raging flame and a huge temperature. What you see under the wing of an airplane is not a turbine, but an aircraft engine. And the turbine is one of its components.

An aircraft engine is a power plant unit of an aircraft that serves to create guaranteed energy and transform it into kinetic energy of movement of the aircraft (airplane, helicopter, cruise missile, airship, etc.).

In fact, everything is much simpler than it seems. The work of an aircraft engine (hereinafter AD) consists of several stages, and to begin with, take a look at the picture below.

This is what the AD of modern passenger aircraft looks like in cross-section.

Now, what does it look like, define the main stages of work from start to takeoff:

✔️Air enters the engine through the air intake. Then it passes through the compressor, where its pressure and light are distributed thanks to special blades.

✔️ Compressed air is directed into the combustion chamber, where the fuel rotates and ignites. As a result, high-temperature gas is consumed when this condition is met.

✔️ Hot gases from the combustion chamber pass through the turbine, where their energy is transferred to the blades, causing them to rotate.

Starting an aircraft engine can take anywhere from 30 to 120 seconds.

✔️ After this, the gases, which have already lost some of their energy, pass through a nozzle. The nozzle has a shape that allows the gases to be compressed, creating a jet thrust.

✔️ According to New York’s Third Law, pushing a jet of gas backward creates an equal but opposite thrust that moves the aircraft forward.

◦ Back to Contents ◬

How much fuel does a modern aircraft engine consume?

Aviation gasoline Avgas-100LL is a leaded fuel specially developed for use in aircraft engines.

Aviation gasoline Avgas-100LL is a leaded fuel specially developed for use in aircraft engines.

When discussing the issue of stopping the work of aircraft engines, the issue of fuel is not discussed. Civilian aircraft use special aviation fuel.

Fuel consumption is one of the advanced technical characteristics of aircraft equipment: the lower the cost, the lower the financial costs and operating efficiency.

The Boeing 787-10 Dreamliner burns 5,700 kilograms of fuel per hour of flight.

The Boeing 787-10 Dreamliner burns 5,700 kilograms of fuel per hour of flight.

Recently, modern civil aircraft have been using aviation gasoline. Fuel consumption depends on external factors: from the weight of the aircraft without cargo to flight conditions and weather.

The unit of calculation is usually considered to be a kilogram of fuel per hour of flight.

For example, the Il-96-400M aircraft consumes an average of 7,977 kilograms of fuel per hour of flight.

For example, the Il-96-400M aircraft consumes an average of 7,977 kilograms of fuel per hour of flight.

Refueling of an aircraft usually occurs at the airport immediately after landing. There is another, less common method – refueling in the air.

This method is used when there is an urgent need to replenish fuel supplies, but there is no way to land the plane.

An example of in-flight refueling.

An example of in-flight refueling.

Refueling an aircraft during flight is a complex procedure that requires great skill and experience from pilots.

To refuel, both aircraft approach each other at a distance of up to 20 meters and are connected by special hoses. The maximum time for such a docking is 45 minutes.

◦ Back to Contents ◬

How passenger aircraft engines are tested

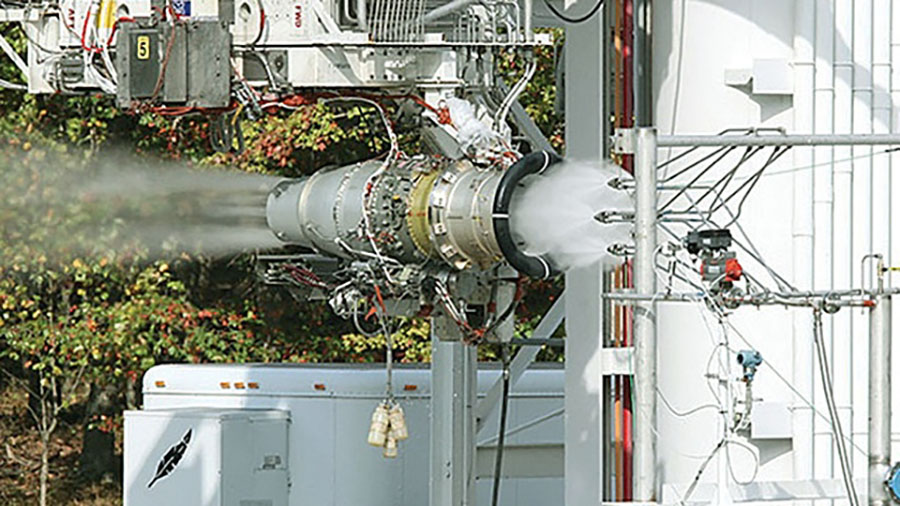

A non-trivial process of testing the engine for strength.

A non-trivial process of testing the engine for strength.

Flight safety, especially in difficult climatic conditions, directly depends on the reliability of aircraft engines. Before installing an engine on an aircraft, it undergoes serious strength tests.

One of the problems that can lead to accidents is icing of engine components during flight. This happens when the aircraft climbs to an altitude of up to 5,000 meters and enters a cold cloud with high humidity. Therefore, it is very important to know that the engine can withstand icing.

Engine icing tests were conducted in a safety installation equipped with a freezing outlet and a system for mixing water aerosol into the air flow entering the engine.

The aircraft is treated with freezing rain, then the engine speed is increased sharply and checked for damage.

The aircraft is treated with freezing rain, then the engine speed is increased sharply and checked for damage.

In addition to the “ice test”, there is also a bird strike test. A bird can get into an airplane engine and disable it. However, for modern airplanes this is not a critical problem, as they can continue to fly, make a fault landing and even take off with one engine.

However, birds often fly in flocks, and in this case all engines can be damaged at once. That is why the engine should be tested for resistance before a collision with birds.

The tests are conducted on a special stand using a cannon. The process is not pleasant: the engine is shot with a bird. Important note: the bird must be alive half an hour before the tests begin.

The tests are conducted on a special stand using a cannon. The process is not pleasant: the engine is shot with a bird. Important note: the bird must be alive half an hour before the tests begin.

And finally, an interesting fact. Did you know that the largest and most famous aircraft engine in the world was developed by a company that produces premium cars? We are talking about the Rolls-Royce UltraFan.

The power of this engine is 85,800 horsepower and manages to create a thrust of up to 50 tons. It is not afraid of birds and extreme weather conditions.

Rolls-Royce plans to install such engines on aircraft in the coming years.

Conclusion

The purpose of this article is to explain in simple terms how an aircraft engine works and to answer the question: “What does it take for an airplane to take off?” I hope I have succeeded.

Do you often fly on planes? Tell us in the comments. Have a great day!

Source: Iphones RU

I am a professional journalist and content creator with extensive experience writing for news websites. I currently work as an author at Gadget Onus, where I specialize in covering hot news topics. My written pieces have been published on some of the biggest media outlets around the world, including The Guardian and BBC News.