A huge number of different cars drive on Russian roads. Sometimes in the stream you can meet new sports cars and old American cars from the second half of the 20th century.

In addition, Russia has a large market for auto parts, some of the cases of coverage of domestic companies.

If we take into account the same Lada Vesta, which is one of the most popular cars in Russia, then many details for its production in the country. AvtoVAZ cooperates with a high interest rate of domestic manufacturers, which account for almost half of the spare parts purchased from Lada Vesta.

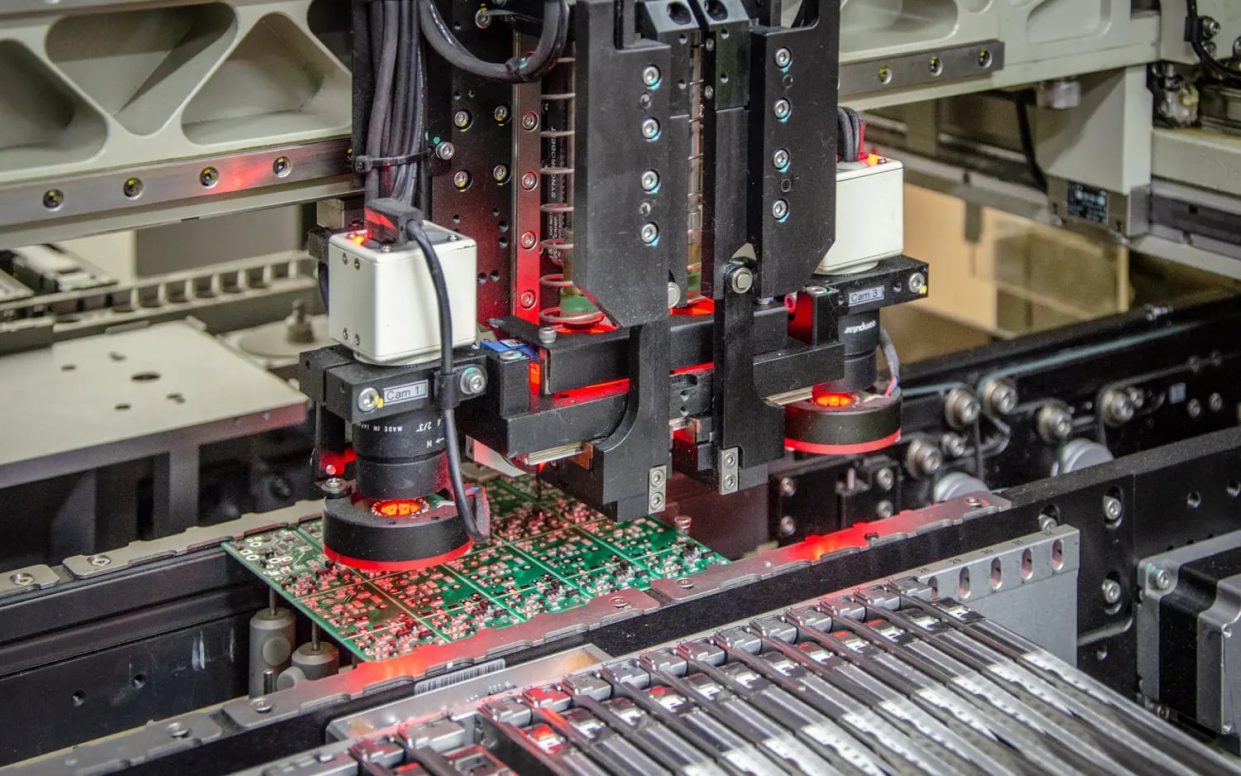

Engine control units Lada: Moscow

The engine control unit is one of the most important parts in a car. In modern cars, including Lada, electronic units are used that actually completely control the car.

It is this part that collects information about all vehicle systems. The control unit is responsible for fuel supply, ignition and engine operating modes. Without this part, the car will not be able to go.

Itelma has been producing engine control units for over 20 years. They are installed in many AvtoVAZ models, including Vesta and Granta.

Suspension parts: 3 companies

From the factory, Lada Vesta comes with a suspension, which consists of members of the Jewish community.

DAAZ Stamp company from Dimitrovgrad, manufacturer of front levers. The front struts and rear shock absorbers are supplied by the Skopinsky auto-aggregate plant, located in the Ryazan region. The ball joint and stabilizer struts in AvtoVAZ come from the BelMag plant in Magnitogorsk.

The suspension of modern Lada is the node with the largest share of domestic components.

Cardan shafts for Toyota and UAZ: Syzran

The cardan shaft is used in rear-wheel drive and all-wheel drive vehicles. It is necessary to transmit torque from the engine and gearbox to the rear wheels.

The KARDAN company was mothballed in 1998 and since then has been engaged only in the production of cardan shafts for domestic and foreign brands, including Toyota, Volkswagen and Hyundai.

Also, KARDAN is a supplier of cardan shafts for all AvtoVAZ, UAZ and GAZ vehicles.

Electronics for UAZ, GAZ and KAMAZ: Penza

Modern cars have a lot of electronics. Domestic automakers tend to order all electronic components from other companies and then demand them on the assembly line.

Penza Plant Electromechanical Measurement (EMI) produces various automotive sensors, relays, switches, starter and turn relays, as well as voltage regulators.

EMI’s clients include many luxury companies such as UAZ, KAMAZ, GAZ, as well as combine harvester manufacturer Rostselmash.

Tires for Ford and Volkswagen: Nizhnekamsk

Car tires for most domestic cars are manufactured by Nizhnekamskshina under the KAMA TIRES brand.

Manufacturer of about 120 different tires for cars and trucks, as well as for trailers, buses, trolleybuses and agricultural machinery. Each year, Nizhnekamskshina produces 4.5 million tires, which are also exported to countries near and far abroad.

The plant’s products are installed in the initial configurations of AvtoVAZ, Volkswagen, Skoda and Ford cars.

AvtoVAZ does not use spare parts Why only from Russian manufacturers

To answer this question, you first need to understand that this is a normal practice for other companies.

The creation of a car begins with the development of a platform and the choice of units. Until 2022, AvtoVAZ was actually a subsidiary of Renault, since 100% strengthening of Lada Auto Holding, a joint venture of the Renault-Nissan alliance (68%) and the state corporation Rostec (32%).

In accordance with the terms of the discussion of the enterprise, AvtoVAZ was obliged to satisfy the requirements of certain Renault and Nissan parts, as well as to use some of their components and parts.

As a result, the Lada Vesta has a Renault rear suspension and steering rack, and the engine has been supplemented jointly with Nissan. There is also a version with a Japanese Jatco CVT.

The choice of components is very dependent on the motor. Each engine manifests itself by its own control unit and is tuned by the gearbox. In addition, the box is not compatible with mechanical action.

After Renault’s departure, AvtoVAZ decided to assemble in Russia with the involvement of completely numerous domestic manufacturers.

New products will be developed on Russian platforms, using Russian engineering competencies and with the maximum involvement of units of account – this is a fundamental decision.

Denis Manturov, Minister of Industry and Trade of the Russian Federation

According to AvtoVAZ President Maxim Sokolov, the development of the rear surface takes 3-4 years. It will be equipped with an engine, automatic transmission and electronic equipment.

Source: Iphones RU