Tesla has taken the electric vehicle market by storm with two of its strongest advantages: its cars break down less often and are less expensive to maintain.

Engine activation is based on the principles of electromagnetism, which has fewer moving parts, no oil changes and less fuel.

And although the principle of its operation has been around for more than 100 years, the basis of this motor was developed in the 20th century. Russian scientist on the developments of Nikola Tesla, Only the new engine in the Tesla Model 3 made a real revolution in electric cars and helped release a truly mass-produced model.

Below, in clear language, we will tell you how the engines in Tesla cars work, how Elon Musk reinvented the century-old level of the electric motor, and why the Model 3 turned out to be more productive than the classic Model S.

Let’s start with a simple base.

How the engine works in all Tesla electric vehicles

To simplify it as much as possible, the engine in Tesla cars works due to two magnetism adapters.

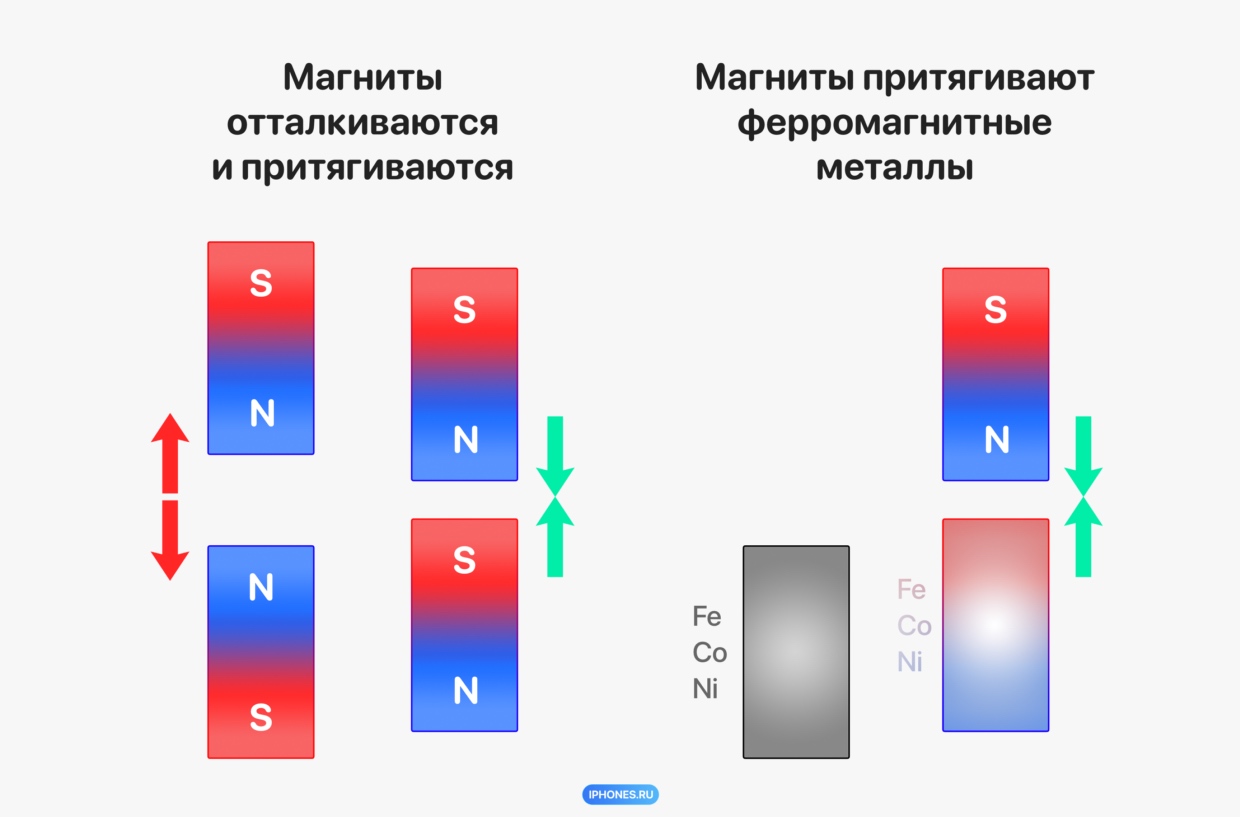

Property 1.

If you move one permanent magnet by the round the second will begin to move. This is because both magnets have a pole with two poles.

Different poles attract magnets, like ones repel each other.

Also, metals without a magnetic field will also be attracted to a magnet. Such metals are called ferromagnetic.

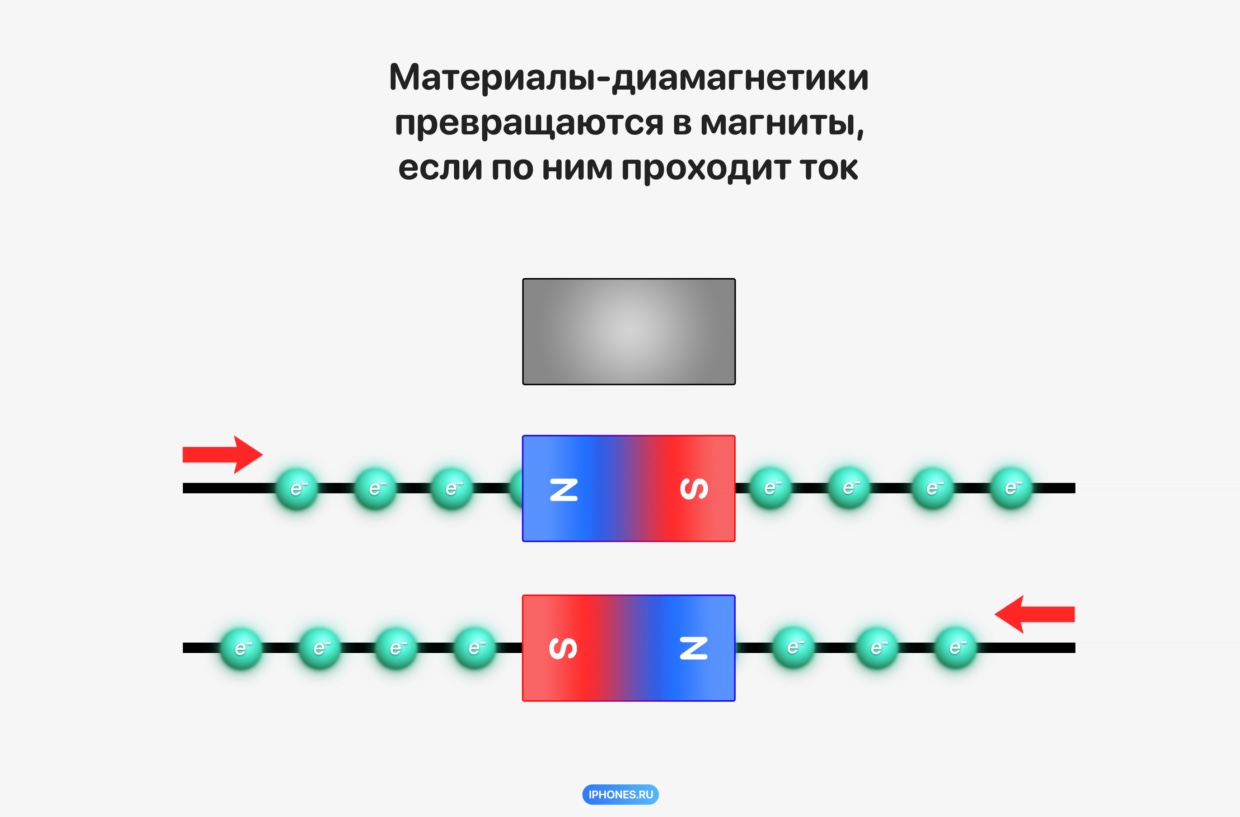

Property 2.

Some metals are not magnets themselves, but if you pass a current through them, they develop a magnetic field.

Such metals and materials are called diamagnetic.

Depending on which direction the current flows in the metal, the position of the magnetic poles will change.

Find such a device AC magnet or electromagnet.

These elementary rules set Tesla in motion, and the engine of any electric vehicle, no matter what design is based on these properties. But the devil, of course, is in the details.

Why Tesla kept outdated technology for the Model S

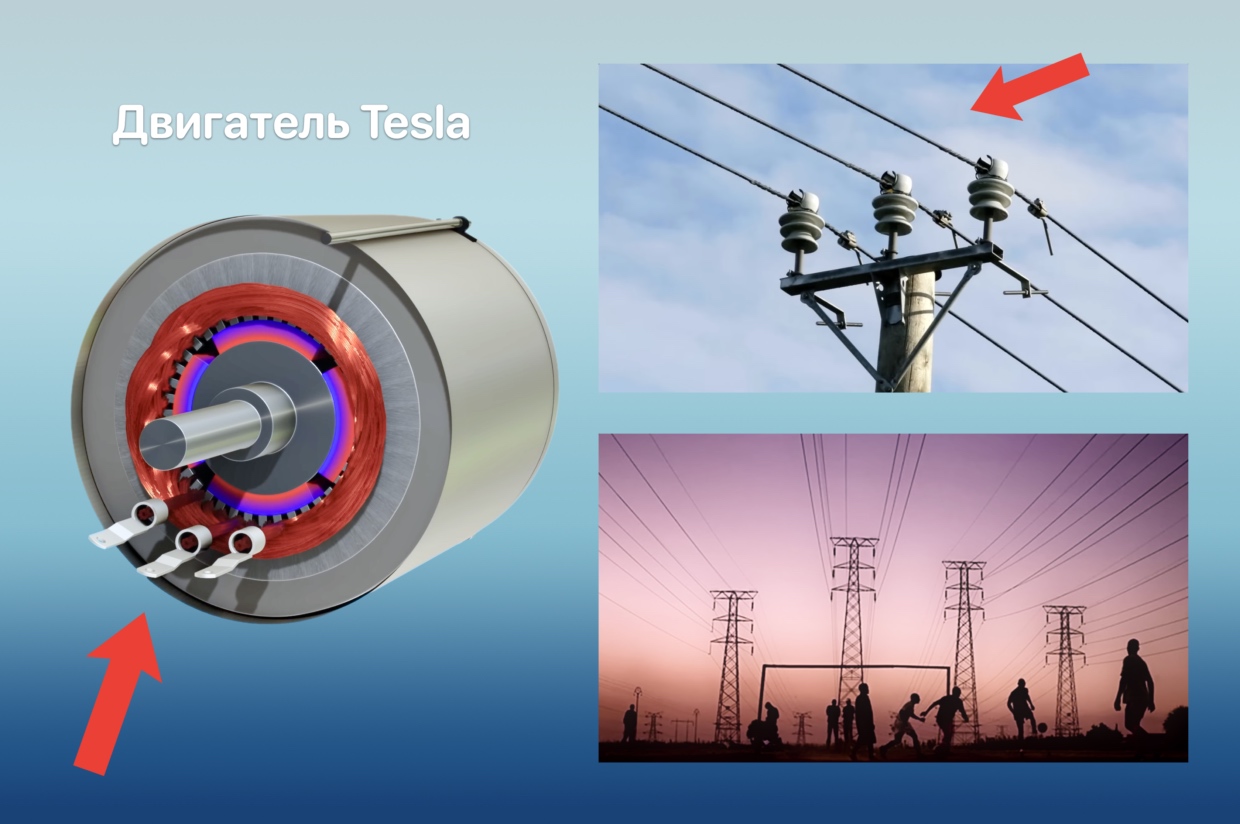

The Tesla motor produces the same three-phase voltage as most modern devices.

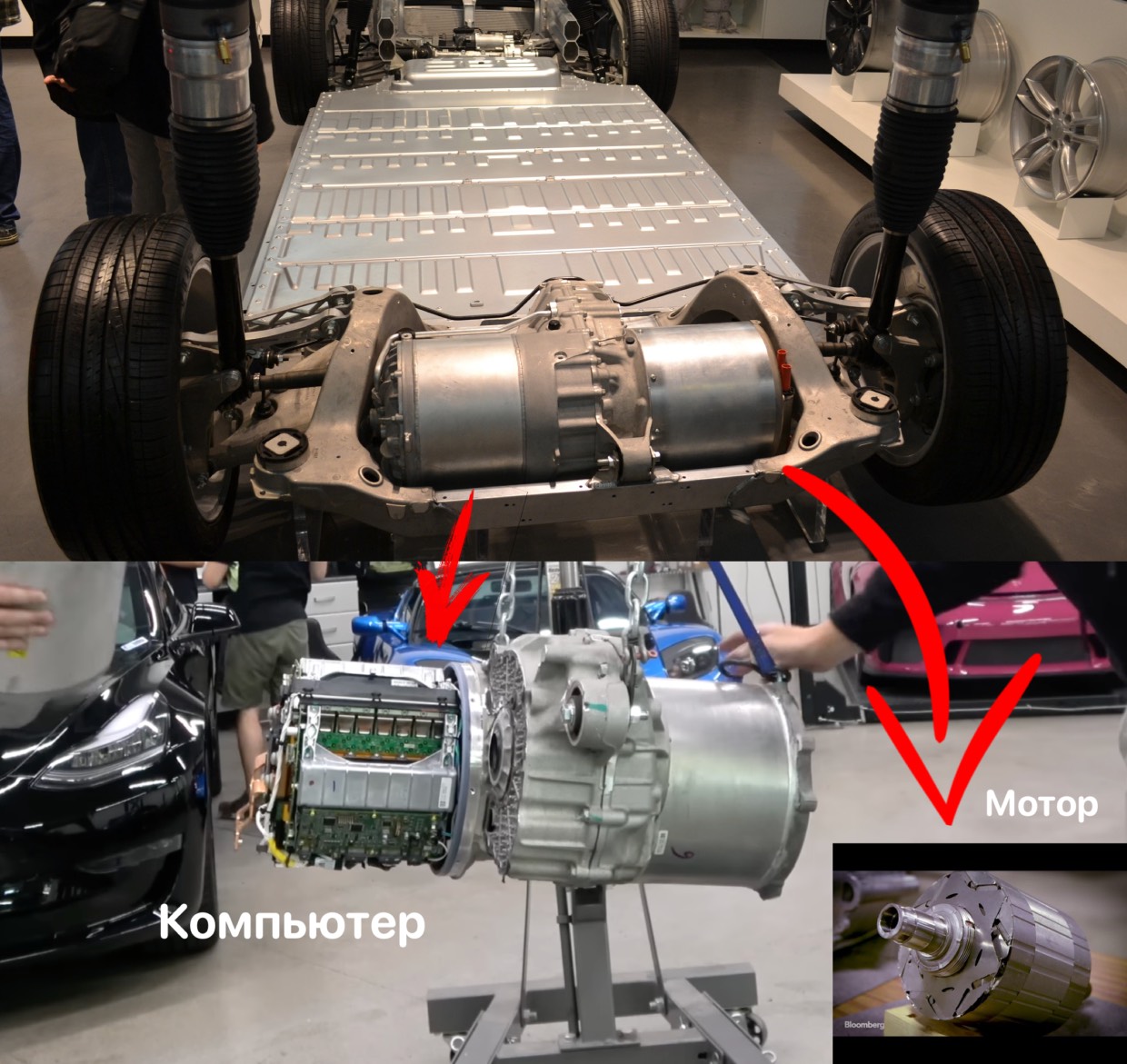

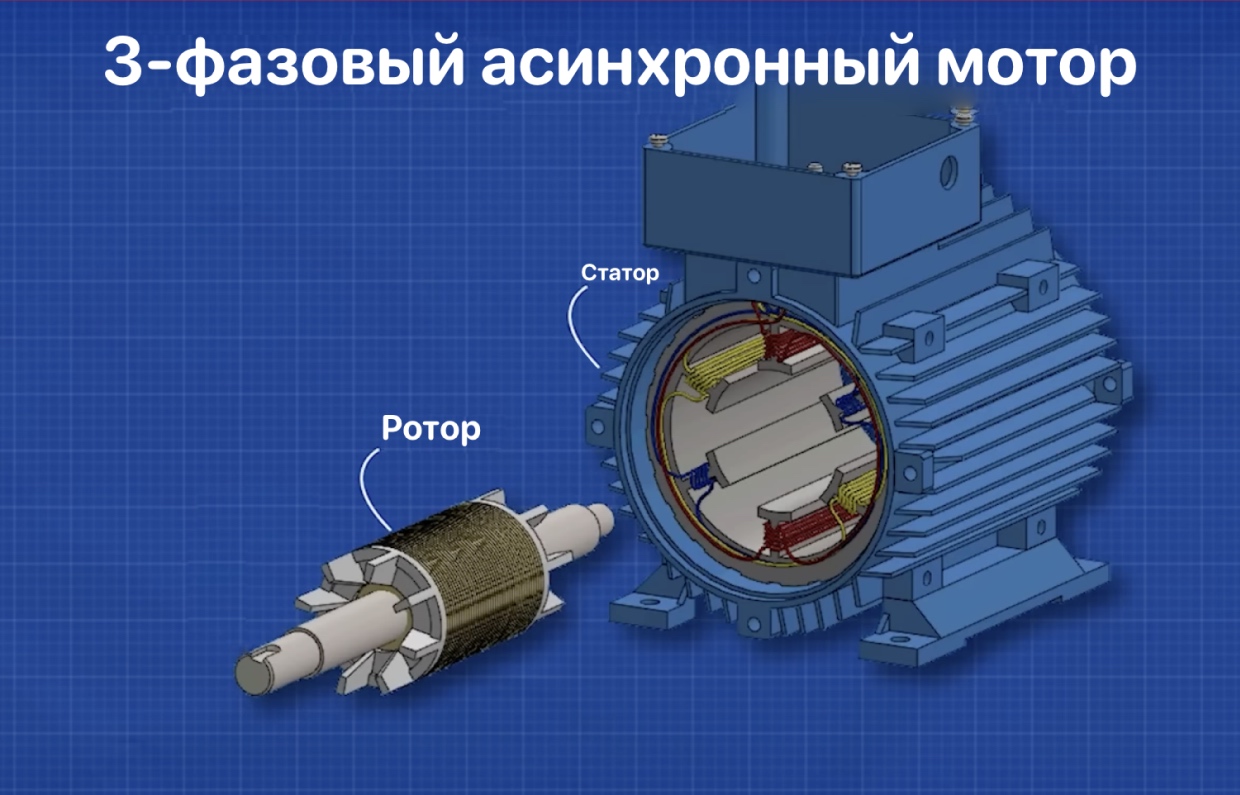

Two main components of the electric motor of Tesla cars. This structure was invented by Nikola Tesla and perfected in order to most effectively use the state of three-phase current Dolivo-Dobrovolsky

In Tesla, for the first time, electricity turned metal into a magnet and turned wheels.

The first Tesla Roadster and Tesla Model S engines used an asynchronous motor. The foundations of his work principles were laid Nikola Teslabut modern premises are developed Mikhail Dolivo-Dobrovolsky.

Its essence is this.

The engine consists of two elements: movable rotor in the center and fixed stator around him.

▪︎ The rotor is a metal cylinder with thick rods around the perimeter, closed rings on both sides.

▪︎The rods are located at an angle and under the influence of magnets. The stator contains an electrical voltage that can turn into a magnet when electricity is applied to it.

▪︎ When three-phase voltage is applied to the stator, as on power lines in any country, the copper turns into a magnet. Due to the rapid change of phases of electricity, its magnetic field causes the rotor to rotate. The car is moving.

This is the absolutely simplest description of the principle of operation of the motor.

Asynchronous such a motor is called because it can only work effectively when the rotor rotates at a higher speed than the magnetic field of the stator, so that the forces are not excluded by another.

This discrepancy is called sliding. It is necessary to create the torque that sets the car in motion.

Thanks to the slip in an asynchronous motor, there is one important property for electric vehicles.

When The rotor rotates faster than the stator, it electrifies the stator, thereby generating energy and charging the car’s battery.

⛔️ Although such motors are efficient, the slip of an induction motor is difficult to control, resulting in energy losses due to the need to constantly maintain the difference in compliance with the rotor and stator magnetic field.

This caused a legitimate problem for a cheaper car.

Why the engine from Model S did not fit the cheap Model 3

The simplicity of asynchronous motors allows them to work flawlessly in washing machines and air conditioners for decades.

But when it comes to a rechargeable device like a car, engineers are always looking for a way to create a more energy-efficient engine.

For example, To maintain the correct state of the rotor during cruise control at a constant speed, up to 4% of the vehicle’s total energy consumption is consumed.

In order to reduce the price, the Tesla Model 3 has 21% fewer batteries (75 kW versus 95 kW in the Model S), which, therefore, would have to completely reduce the driving range on a single charge.

The company began to think about how to improve the mechanism.

What recipe was it decided to use for model 3. And why didn’t it work the first time?

There is a more efficient motor in which permanent magnets are included in the rotor core. They move at the same time as the field, providing a faster and less expensive start.

This engine is called synchronous.

By taking into account the constant magnetic field, such a motor begins to move faster when an electromagnetic field is formed in the stator.

The challenge was to make an engine based on this technology that would be reliable enough for use in cars.

But this decision, in the singular, had its downsides.

This technology is ideal for ignition and acceleration, but consumes a lot of energy when moving at a constant speed.

🔩 Due to the sudden switching on, the magnets must be fixed so that they do not fly apart due to centrifugal force and the motor does not break.

🧲 In addition, permanent magnets, when moving quickly, themselves produce electromotive force, which generates voltage in the stator, the opposite of what acts on it with the help of batteries. This is a decrease in the strength of the stator magnetic field and another heating option.

Despite these shortcomings, they still decided to use this when developing Model 3. synchronous a motor with permanent magnets added inside.

But the problems of reliability and efficiency were solved by what they did in the rotor… holes.

How Tesla solved the problem of a new engine for Model 3

For a motor with permanent magnets it was suitable not only for acceleration, but also at constant speed; in Tesla, in addition to placing permanent magnets, metals of the same interesting property were also used.

The traditional cylinder of looped metal beams in the rotor was replaced by a solid iron core, in which hollow V-shaped cutouts were made.

These cutouts, even without permanent magnets, allow the rotor to move synchronously with the stator’s magnetic field due to the low resistance of iron to the magnetic field.

Thanks to this, a special structure was formed inside the rotor, which began to move in the presence of a magnetic field.

Such mechanics perfect suitable for maintaining constant speed while driving.

But such a mechanism is not suitable for igniting and starting a car.

And then Tesla came to an elementary solution.

✅Hole method of supplying permanent magnets from a synchronous motor, which is ideal for uniform acceleration.

This creates a new rotor that combines low-resistance iron with the effect of permanent magnets.

The angle at which the magnetic fields of the rotor and stator relate to each other is adjustable and installed directly in the computer’s motor.

Its algorithms are one of Tesla’s main achievements, thanks to which the company has an advantage in the efficiency of cars in distributing energy.

Thus, it sets the position of the magnetic fields under different scenarios: ignition, acceleration, braking and maintaining speed.

This will reduce energy consumption over the entire trip and comply with ignition saving measures as cars use more energy.

In this motor, the rotor moves synchronously with the magnetic field of the stator to achieve maximum efficiency between the permanent magnets, the holes in the iron core of the rotor and the magnetic fields of the stator.

that’s why the engine was named IPM SynRMwhat does it mean Internal permanent magnet, synchronic, jet engine or “Internal permanent magnet, synchronous, magnetic reluctance.”

Essentially, the name simply translates the essential elements that help an engine run more efficiently.

How Tesla plans to change the engine again

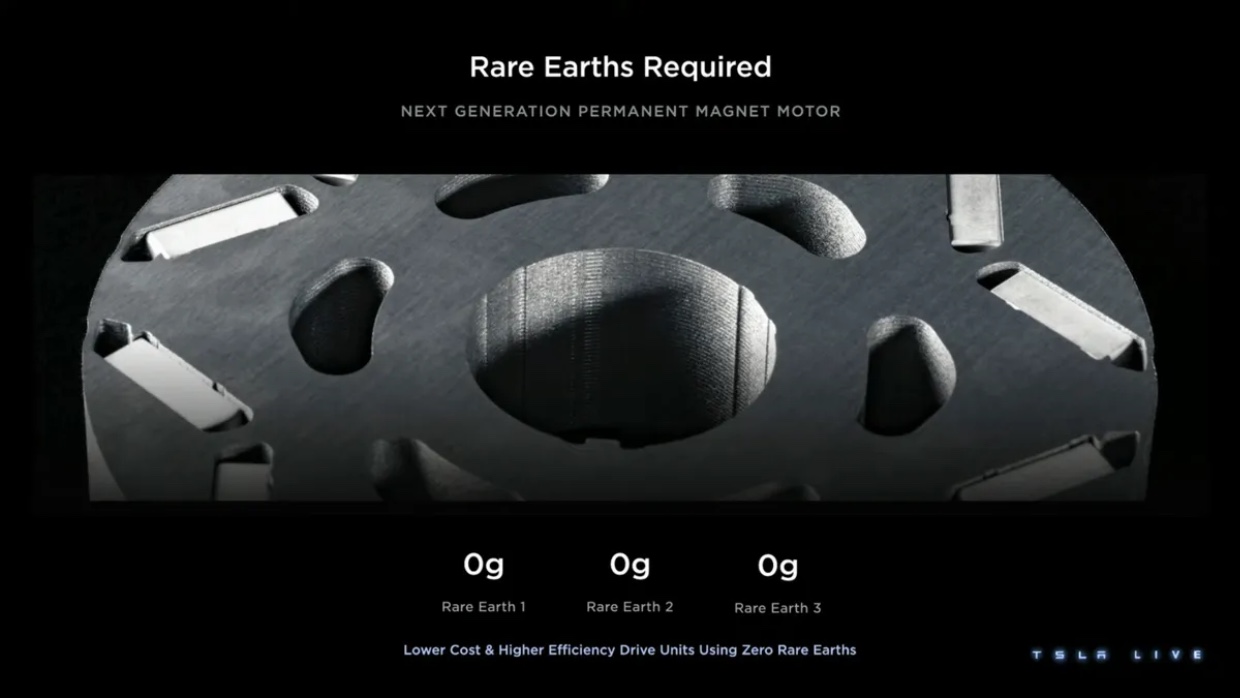

Current permanent magnets in Tesla motors made from neodymiumwhich is classified as rare earth and therefore increases the cost of production of car engines.

That one will probably be replaced by a more common one ceramic ferritewhich is used in speakers, electric guitars, drills and refrigerator doors.

The company has already announced a transition to more affordable materials.

Nowadays, ferrite is not used because neodymium has a much stronger magnetic field, and for the same attractive force you would have to use more ferrite.

This results in a reduction in acceleration from 0 to 100 km/h, which is a record figure used on commercial vehicles by the famous Tesla.

However, in, say, a taxi, this parameter has absolutely no meaning for the end user.

And so the autonomous robotaxi, also known as Tesla’s Cybercab, will be created as a candidate to power the next generation of engine.

We took a ride on the Cybertruck in Moscow and found the pros and cons. Impressions from the outside world Tesla Cybertruck Cyberbeast

Source: Iphones RU

I am a professional journalist and content creator with extensive experience writing for news websites. I currently work as an author at Gadget Onus, where I specialize in covering hot news topics. My written pieces have been published on some of the biggest media outlets around the world, including The Guardian and BBC News.