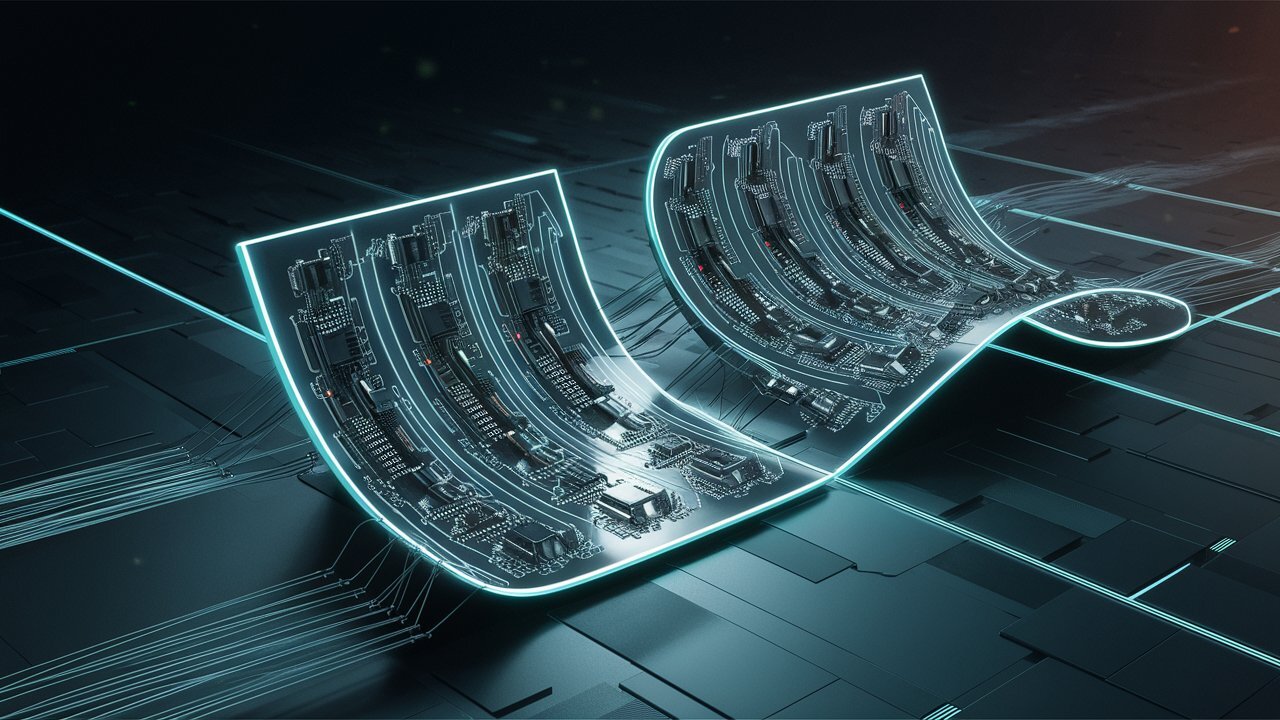

Flexible polyamide boards have some advantages compared to traditional fiberglasses: they are lighter, more elastic and more resistant to high temperatures. However, processing has always been a difficult task due to the excessive flexibility of the material that prevents the right drilling.

Production Association “Electribrebor” (part of Rosel) experts, polyamide workpiece between two -fold auxiliary material found a solution. The lower wood fuel sheet layer with a special coating provides an equal surface and presses the top of the top aluminum layer and prevents displacement. This allows you to obtain drilling up to 20-25 microns.

According to Alexei Troshin, General Manager of JSC “Electric Priva”, the company dominated the production of bilateral boards of the 5th accuracy class and in some cases even in the elements of the 6th grade. The size of the products varies between 24 × 30 mm and 345 × 313 mm.

Source: Ferra

I am a professional journalist and content creator with extensive experience writing for news websites. I currently work as an author at Gadget Onus, where I specialize in covering hot news topics. My written pieces have been published on some of the biggest media outlets around the world, including The Guardian and BBC News.