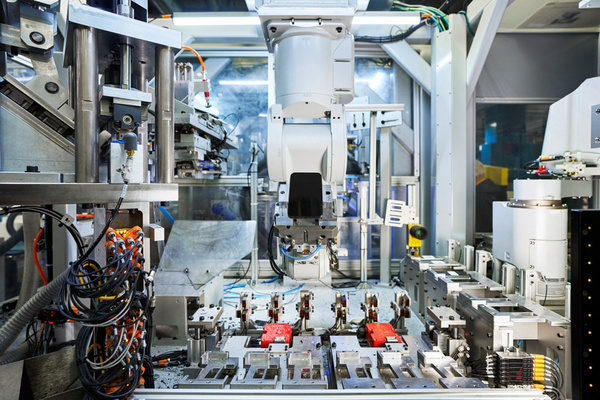

Apple is trying to use more recycled content in its phones than ever before. As part of these eco-friendly plans, the company introduces us to Taz, its latest recycling robot. Taz is designed to intelligently disassemble and separate those electronics parts of the iPhone so that workers at Apple’s Materials Recovery Lab in Austin, Texas, can extract precious and rare earth metals. These elements, including gold, tungsten, cobalt, and tin, are needed to manufacture circuit boards, batteries, and cases for all Apple devices, in turn.

The Taz isn’t the first fully automated robot built by Apple to recycle its old electronics. In fact, it’s the third in the series that completes Liam’s replacement Daisy. The old model, which Apple claims will recycle 200 iPhones per hour, can now disassemble 23 different iPhone types. Liam came out in 2016 and Daisy followed in 2018.

Daisy

The new robot differs from Daisy in that its mechanisms are specifically designed to smash certain iPhone parts that Daisy cannot completely separate. For example, shredding automation makes it possible to separate magnets from sound modules and shred parts in a way that allows Apple to collect rare earths. Taz will allow Apple to further expand its process of using recycled materials for new products. For example, the iPhone 13 and iPhone 13 Pro were the first Apple products to use certified recycled gold from the company’s own production. Apple products released in 2021 also include recycled tin, recycled cobalt, and some certified recycled rare earth metals in their making.

tazu

Apple also announced that it is using a third robot, named Dave, to disassemble the Taptic Engines in iPhone and Watch devices. Inside every Taptic Engine is some precious tungsten and steel that Apple aims to recycle and reuse in its future products. Learn more about Apple’s sustainability efforts in the 2022 Environmental Progress Report.

Sources: Apple, Slashgear

Source: Hardware Info