Ford just found the perfect key to make cheap electric cars. Or, at least, it seems on paper. The truth is that this is nothing new, but it can be a starting point for a huge future American company of an American company: a universal platform.

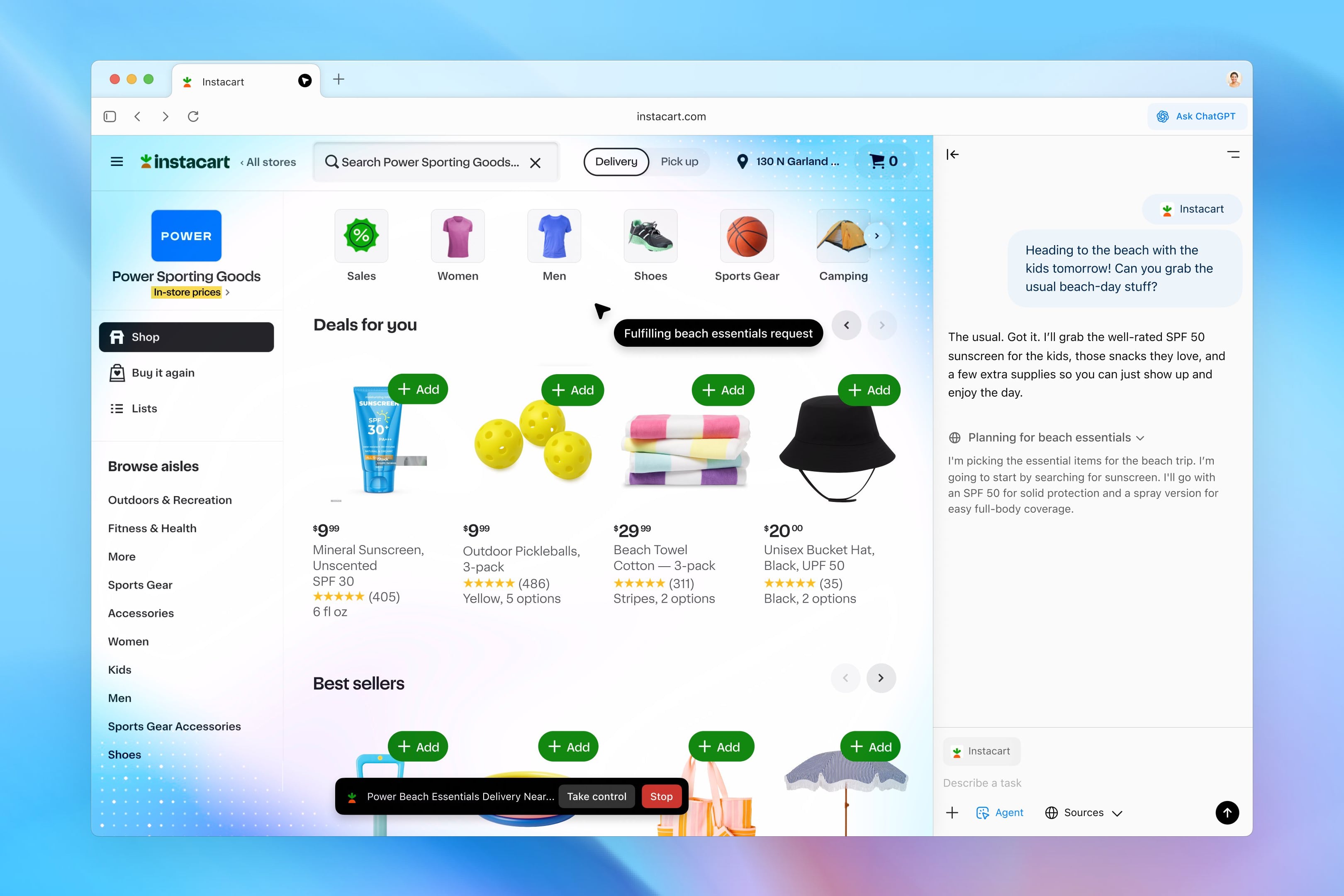

The idea of Ford is simple: the combination of the production of all models within the same structure is already through the modular platform. At the same time, production costs are reduced when part of the scale savings between different models, and most importantly: simplifies (and low) most of research and developments and combining many developments – battery, software or even robotics – for their use in several models.

The plan, which will be intended for the United States at the moment, will begin with the receipt of the average size, which will begin with $ 30,000 and will begin to be produced in 2027. Therefore, the company will begin this plan to create a family of inexpensive electric vehicles using the platform of this first model.

This Ford platform, on paper, tExalually scalable and adapted to most models that the company sellsIncluding trucks, vans and large SUVs.

Ford plan allows you to make an electric car easier and cheaper

Therefore, they will share many elements, such as some of the structures, software (which will be updated over time) or key sections of electric vehicles, such as the battery system that this time will have iron and lithium -phosphate (LFP), which promise to be longer, more rapid loading and, above all,, first of all,, first of all,, first of all,, first of all,, first of all,, first of all ,, cheaper than those used todayAll to reduce the cost of production.

And, being Ford, the company standing behind linear production, the entire production process of this new platform will operate as the only model assembly line that operates as a kind of “assembly tree tree”, in which several assembly lines begin independently, and then join. Which allows Make unique sections of each model and are completed with those who share the entire platform.

According to Ford, this new unique platform uses 20% less pieces than a traditional vehicle, 25% less than the mounting system and 40% less workstations at each factory, which is a huge savings in production costs and increasing production speeds. In a nutshell, Let it be “easier” to make cars.

At the moment, yes, there are no new cars, in addition to the declared truck, and the second is only a prototype. Nevertheless, it seems that this will be a long Ford plan, and that its implementation, although inevitable, will still undertake to give tangible results.

Source: Hiper Textual

I’m Blaine Morgan, an experienced journalist and writer with over 8 years of experience in the tech industry. My expertise lies in writing about technology news and trends, covering everything from cutting-edge gadgets to emerging software developments. I’ve written for several leading publications including Gadget Onus where I am an author.