Russia ranks third in the world in oil production and second in gas production. According to this indicator, it is second only to the United States and Saudi Arabia.

In 2023, Russia produced 10.35 million barrels of oil daily. The easiest way to extract oil is an offshore platform.

This is a large structure that should not only produce oil, but also offer additional technologies against disasters and the prevention of environmental disasters.

There are 15 offshore oil platforms in Russia. The largest of them, Berkut, is also the largest in the world. This is an international project of Rosneft, the construction of which cost $12 billion.

Brief description

How are preparations going for the construction of the platform?

What does an oil and gas platform consist of?

How life works on the platform

How oil is extracted

When will Berkut finish work?

How are preparations going for the construction of the platform?

Construction of the underwater foundation of the Berkut

The creation of any oil and gas platform includes several stages:

▶︎ Design

▶︎ Manufacturing

▶︎ Transportation

▶︎ Installation

▶︎ Login to the application

Building a platform requires years of planning and design, which takes into account the characteristics of the site itself and the location where it will be installed. Engineers need to carefully study the environmental conditions such as water depth, wave height. The platform should be slightly movable to facilitate the flow.

Depending on the place of birth it will work and how the mining will be carried out, the requirements for the installed equipment, which is manufactured to order, will also change.

What were the difficulties with logistics?

Delivery of the Berkut underwater support to the Sea of Okhotsk.

After design, the manufacturing process begins. Generally, construction is carried out in different regions, usually in different countries, and then all the details are prepared in sight until the evening where the platform will be installed.

Platform components are made from the highest quality materials. Often, the construction of a platform contributes to the development of the economy in the region where it is carried out. For example, to build the foundation and support of the Berkut, two concrete plants were built, and 2,000 people worked on the construction site.

Delivery of all platform parts is also a complex process, primarily from a logistics point of view. For major transport components such as foundations, top modules and drills, it is necessary to rent a fleet of specially trained ships and crews.

Implementation planning at the implementation stage, because you need to spend several months just preparing for transportation. It will not happen without force majeure.

Berkut drilling rig

The shut-off valve for the Berkut, which is needed to ensure a uniform flow of oil, had to be quickly delivered to South Korea from Italy due to the acceleration of construction.

An An-124 Ruslan cargo aircraft was brought in for this purpose. However, Busan Airport, which is closest to the construction shipyard, could not accommodate such a large aircraft. Then it was decided to land it in Seoul, transport the cargo to the port and send it to the shipyard on a barge.

This installation step is usually performed at the site where the platform will be located. It can last for several months. During installation, all platform components are connected to each other, and systems for its life support are configured.

The final step is various inspections that check the platform system before jobs are delivered to it and oil production begins.

◦ Back ◬

What does an oil and gas platform consist of?

The construction of the Berkut platform began in 2009, and it was put into operation in 2014. This is part of the large-scale Sakhalin-1 project for oil and gas production near Sakhalin Island.

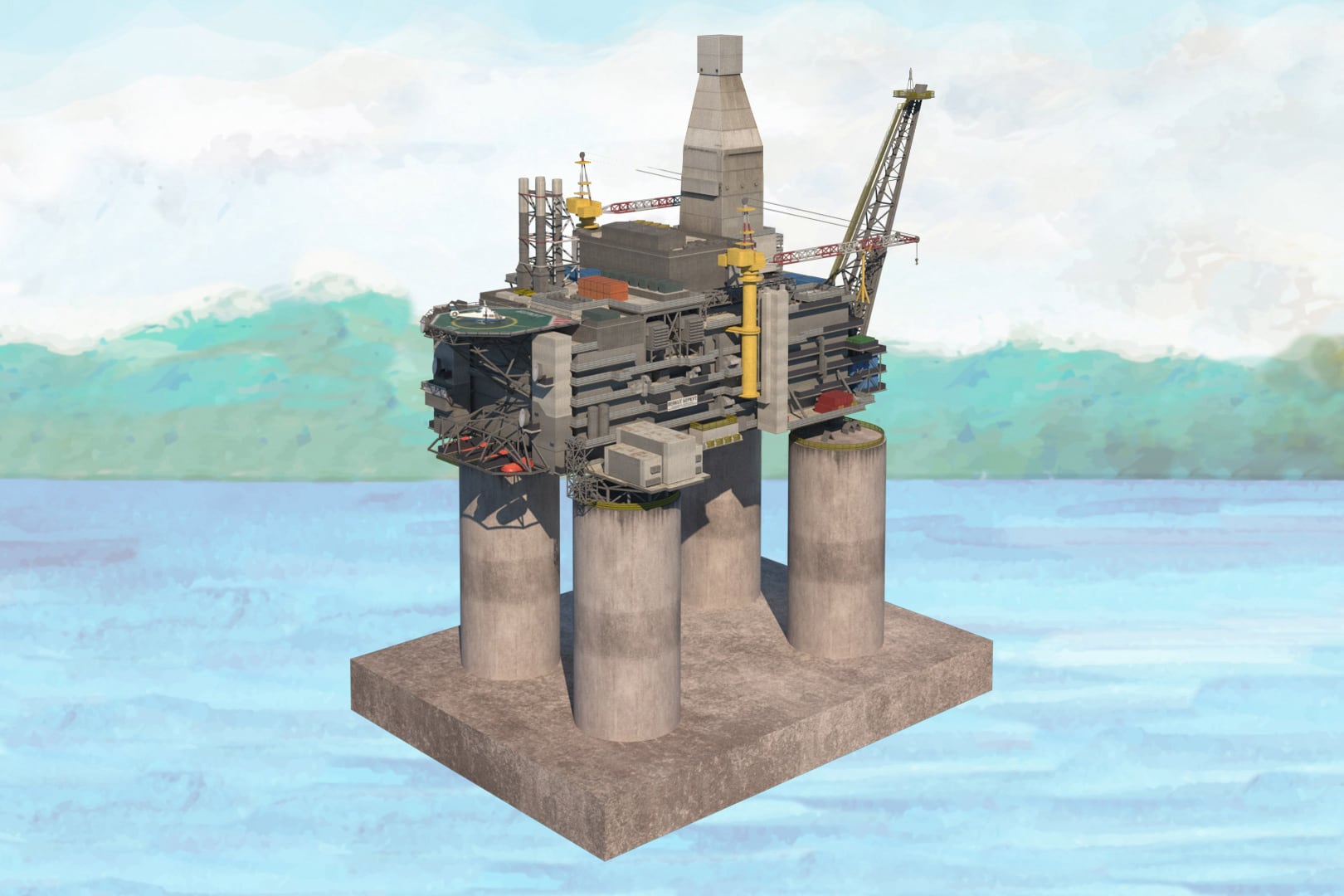

“Berkut” is a stationary platform consisting of a surface module and an underwater foundation fixed to the seabed.

“Berkut” in numbers

▶︎ The base of the platform consists of reinforced concrete slabs measuring 134 x 101.4 meters and a height of 13.4 meters.

▶︎ This slab is supported by four columns with a height of 54.6 meters and a diameter of 25.6 meters to support the upper module.

▶︎ The weight of the foundation alone is 160 tons.. It is installed at a depth of 33.6 meters in the Sea of Okhotsk.

What technologies are used in construction

Berkut scheme

After installing the foundation, the upper module was installed on it, which was built in South Korea. By the way, the platform was built in the city of Nakhodka, the drilling rig was built in Kaliningrad. In total, 20 countries took part in the construction of Berkut.

The upper module, including all equipment and a living block, is installed in special holes on concrete platforms. The places where the structure and mounting module are installed are connected to supports covering reinforced rubber bearings. This is necessary to ensure that the platform remains stable during earthquakes up to magnitude 9.

“Berkut” is designed to operate in temperatures down to -44 ℃. and a storm in which the wave height reaches 18 meters. This is partly why she has such thick supports.

◦ Back ◬

How life works on the platform

“Berkut” accommodates 240 people. This is a safety requirement because lifeboats are designed to accommodate this number.

The platform itself is located 25 kilometers from the northern part of Sakhalin Island, on the shelf in the Sea of Okhotsk. It takes 40 minutes to fly from the nearest settlement to the platform by helicopter, and 8 hours to the sea by ship.

Work on the Berkut takes place on a rotational basis. Employees are expected by helicopter. But there are situations when, due to bad weather, the helicopter arrives several days later than planned. Provisions and equipment are delivered by ship.

The height of the platform with suspensions is 144 meters.which is equivalent to a 50-story building. The upper module has a height of 6 floors. It includes many technical rooms and a living compartment.

Each room has a table, wardrobe and bed. In a small hallway there is a toilet and shower. There are rooms designed for two. The facility has a large canteen that is open 24 hours a day.

Now everyone on the platform speaks English. Until 2022, the main language was English because there were workers from other countries.

The Berkut has its own electric generator, which supplies electricity to the entire platform. It runs on gas, which is extracted from underground. There is also a sea water purification system.

All waste on the platform, including household waste, goes back underground through a separate well.

◦ Back ◬

How oil is extracted

Scheme of oil production on a stationary platform

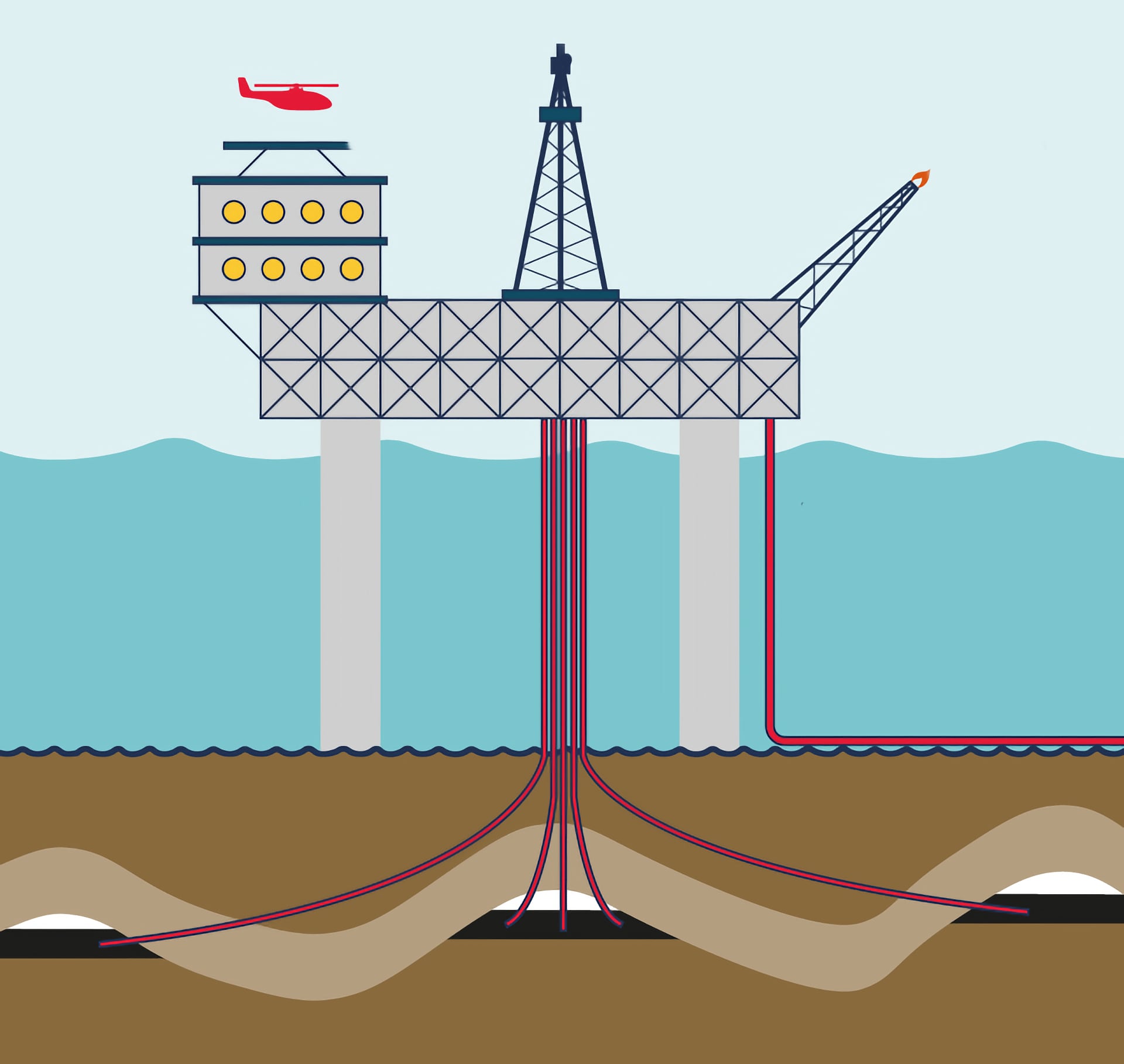

To reach the birthplace of oil, it is necessary to drill a tunnel underground, which can be several kilometers long. It all depends on where the oil is located.

Drilling does not occur vertically, but in an inclined direction, because the oil is not directly under the platform, but next to it. In addition, the pool can be isolated from each other. The drill is made of high-strength steel, and the sharp elements are made of artificial diamonds.

Ten wells are consumed on the platform underground (Berkut is designed for 45 wells). The most difficult task is to ensure that when drilling one well the others are not affected. Navigation on the ground is carried out using telemetry systems.

Oil production monitoring pressure equalization. To prevent oil from gushing out of the well like a giant fountain (there is very high pressure underground), it is pressurized with compressors installed on the platform.

The oil coming from the well flows onto the platform into one large pipe, and material flows through it.

Berkut calculated 12 thousand tons of oil per day. This is 4.5 million tons of oil per year.

◦ Back ◬

When will Berkut finish work?

“Berkut” is designed to operate until 2040-2050. The final date will be kept from the rate of oil production.

Once the work is completed, all wells are purchased to prevent future leakage, and the platform itself is dismantled. First, the upper module is removed in parts, and then the foundation.

This is also a complex and complex procedure that can take several years. But so far this is not discussed.

◦ Back ◬

It’s even more interesting to expand your horizons 🙌

▸ This new bridge in China broke 10 world records at once. It is patrolled by robots, there are no goods in the world

▸ What happened to the scientist spaceship Buran. This is the USSR’s response to the Shuttle from the USA, which was abandoned

▸ This crazy Soviet all-terrain vehicle “Kharkovchanka” traveled around Antarctica for 60 years. There are still no analogues to it

Source: Iphones RU

I am a professional journalist and content creator with extensive experience writing for news websites. I currently work as an author at Gadget Onus, where I specialize in covering hot news topics. My written pieces have been published on some of the biggest media outlets around the world, including The Guardian and BBC News.