Researchers at Concordia University have developed a new 3D printing technique that uses extremely sensitive sound waves to momentarily make particles extremely hot. The Direct Audio Printing technique ‘presses’ objects by temporarily heating the particles to attach them to the printing platform or a pre-printed ‘pixel’. This creates pre-programmed 3D objects.

The technique currently works, for example, with liquid polydimethylsiloxane material. Focused ultrasonic sound waves can heat the polydimethylsiloxane particles in the surrounding liquid to about 15,000 degrees Celsius, creating a pressure of more than 1000 bar. This happens in a trillionth of a second. In that short moment, the particles in question harden in a very sensitive place.

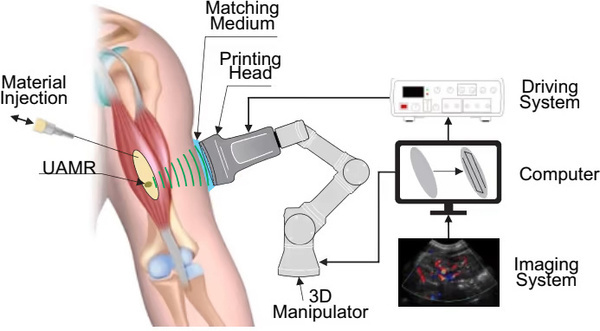

One of the striking features of this printing technique is its ability to direct sound waves behind a barricade. In other words, using Remote Distance Printing, particles could theoretically be printed behind a physical wall or human skin. According to the researchers, this principle could be applied in medical science, for example, by printing biomedical material on the human body.

One possible application of Direct Sound Printing is the printing of 3D structures in the human body.

Sources: Nature.com, via NewAtlas

Source: Hardware Info