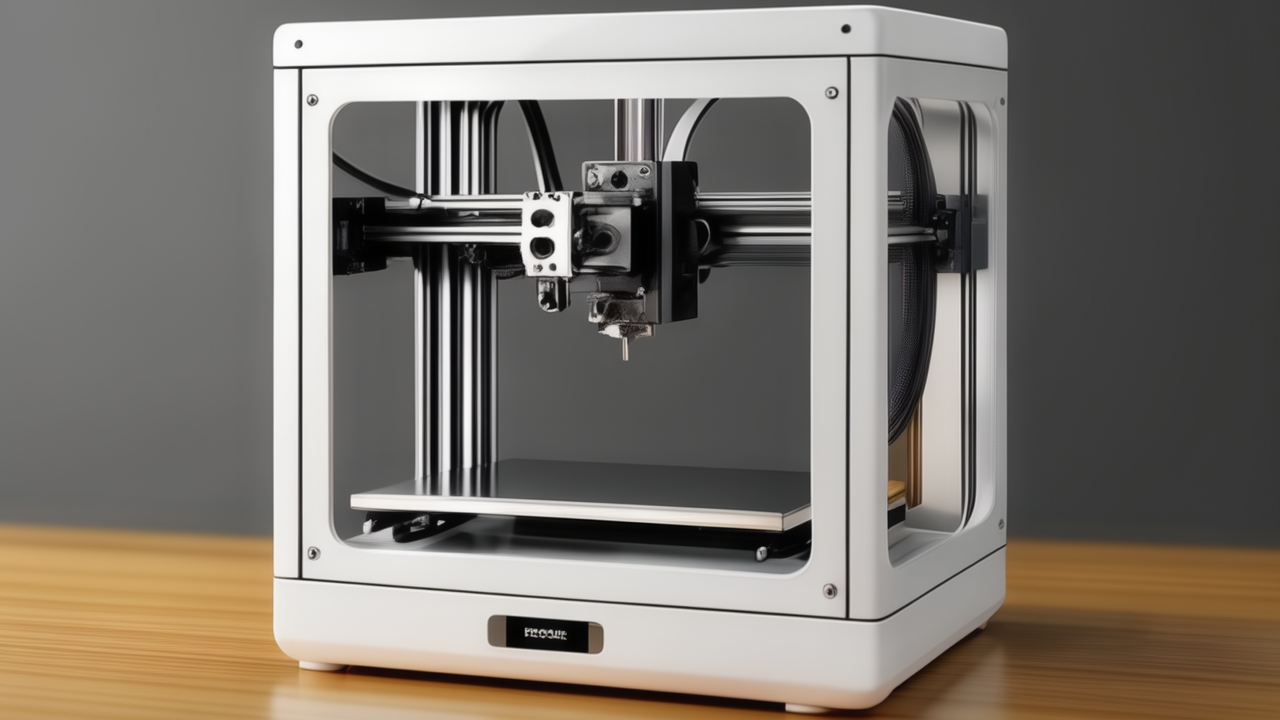

The process developed by mechanical and aerospace engineering professor Yong Huang and his colleagues allows manufacturers to create objects in a cost-effective and environmentally friendly way. This innovative approach is described in the journal Nature Communications.

According to Huang, the new method is more cost-effective and simpler than existing technologies; This makes it possible to print advanced materials, including metals.

To understand the process, you can imagine that special environmentally friendly liquids are used as “ink” in a 3D printer. When printing with these liquids, solvent vapor is introduced into the printing area, causing the liquid portion of the ink to solidify, leaving a solid material behind; this is phase separation caused by steam.

Huang explains that the process allows manufacturers to create spatially tunable, multifunctional parts with multi-level porosity, meaning structures can be created with different materials and at different porosity levels in different locations.

The VIPS-3DP method is also an environmentally friendly option compared to traditional printing methods as it uses sustainable materials and consumes less energy.

Source: Ferra

I am a professional journalist and content creator with extensive experience writing for news websites. I currently work as an author at Gadget Onus, where I specialize in covering hot news topics. My written pieces have been published on some of the biggest media outlets around the world, including The Guardian and BBC News.