According to preliminary data, the efficiency of the device will be 25 kg/h and the manufacturing error will not exceed 1 mm. Including for products up to five meters.

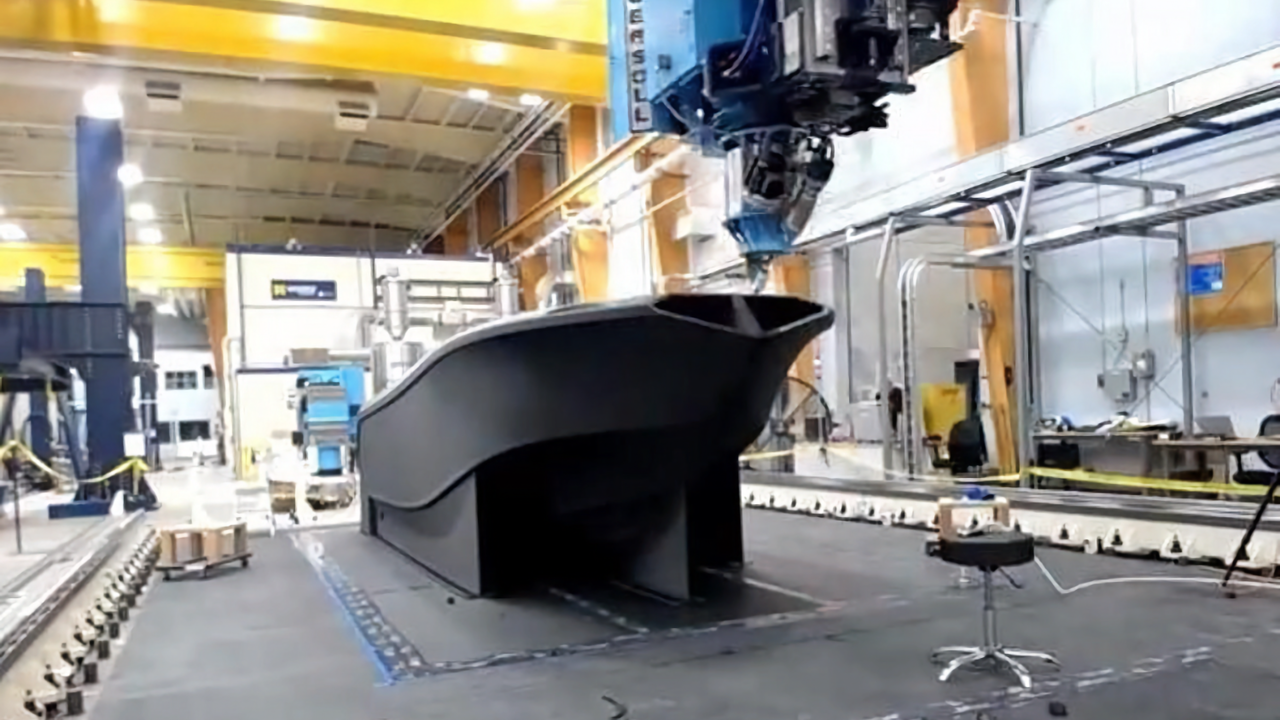

It is reported that MORTECH plans to use the new printer to produce ABS plastic ship equipment with a milling head precision of 0.1 mm. Thus, the company plans to produce up to 48 ship hulls per year.

It is known that new designs will be lighter and stronger than their current counterparts, thanks to modern composite materials. Only two employees will be required to service the innovative equipment, which is scheduled to be operational by the end of 2024.

The company also noted that it has invested in its own industrial 3D printer, which will enable 100% localization of the final product. Both in terms of raw materials and components and in terms of production equipment.

Source: Ferra