Traditional implants are made of expensive import materials to restore bone tissue. SFU experts suggested an alternative biopolymer that produces special bacteria fed with organic wastes. This allows you to reduce the production cost about half.

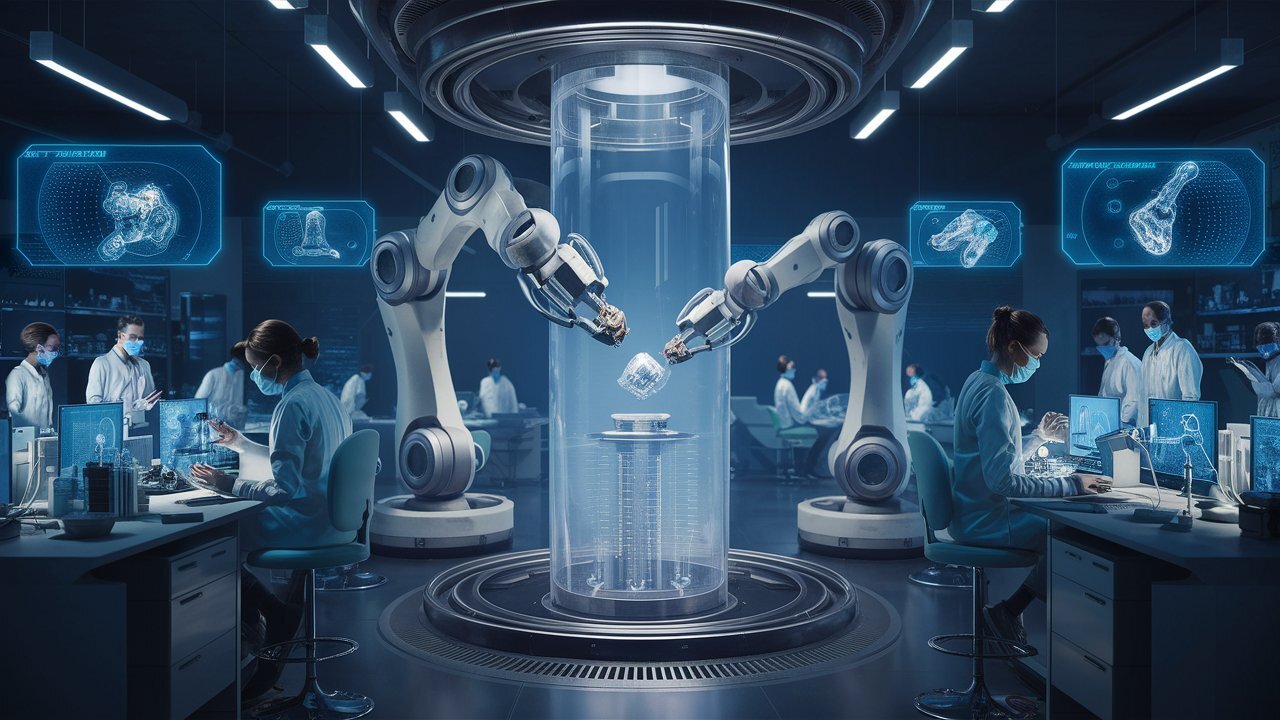

The implant production process begins with computed tomography of the damaged area of the bone. Later, a 3D model of the future implant, which is printed on a special printer from a biopolymer thread, is created. All components including bacterial strains and equipment, Russian production.

One feature of development is the porous structure of implants that contribute to the rapid growth of bone cells. As the experiments show, various pore forms are equally effective for the restoration of the fabric. This can save patients from repeated operations.

Source: Ferra

I am a professional journalist and content creator with extensive experience writing for news websites. I currently work as an author at Gadget Onus, where I specialize in covering hot news topics. My written pieces have been published on some of the biggest media outlets around the world, including The Guardian and BBC News.