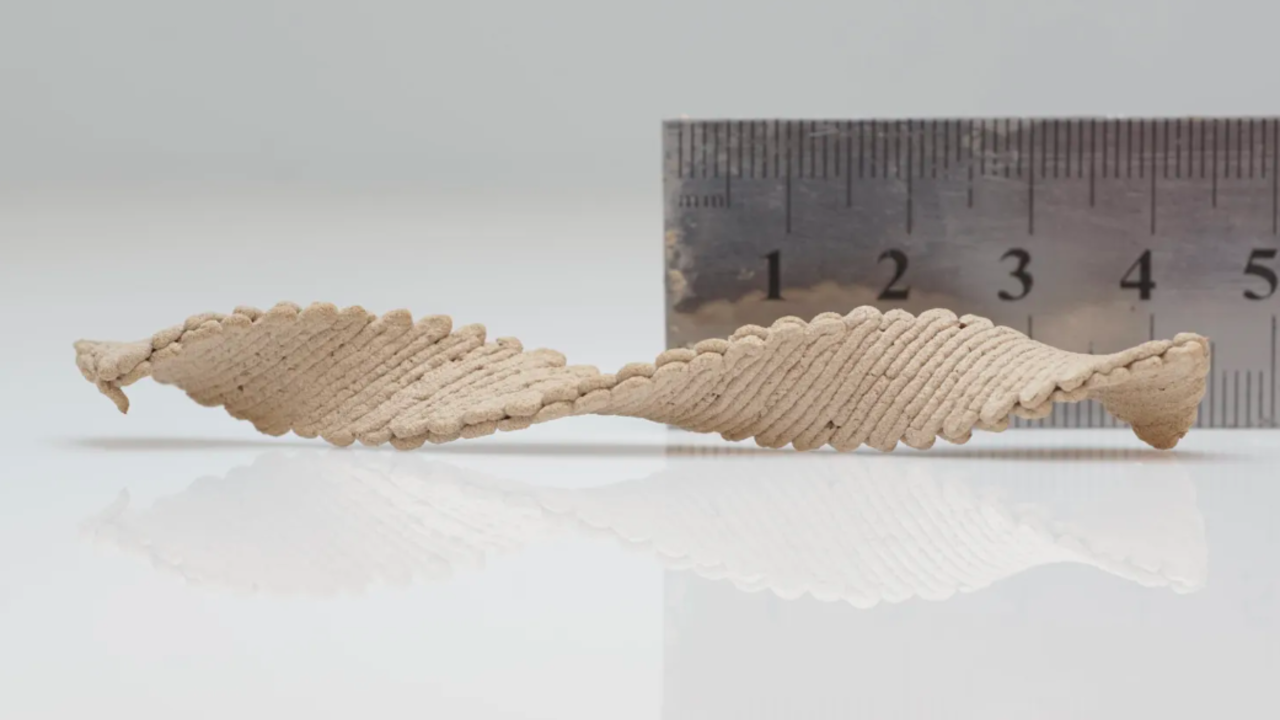

3D-printed wooden objects can be programmed to form complex shapes by a team of scientists. The authors of the development say that the new technology will reduce the cost of delivery to the destination. When the product is taken out of its packaging and starts to dry, it takes the desired form.

The technology was developed almost by accident. A few years ago, researchers created an environmentally friendly water-based ink made from wood waste microparticles. “Wood meal” was mixed with cellulose nanocrystals and xyloglucan. They decided to use this ink in a 3D printer. It turned out that as moisture evaporates, the way it is applied determines the change in shape of the product. The final shape can also be controlled by adjusting the print speed.

Now scientists have learned how to program print speed and direction to produce different final shapes. Further refinement will enable researchers to obtain objects with complex final shapes, such as chairs.

Source: Ferra