Manzana would cancel his plan to produce his own microLED screens for Apple Watch. According to rumors, Cupertino residents have put an end to an initiative aimed at minimizing dependence on Samsung and other component manufacturers. The report comes weeks after the Apple Car, one of the company’s most ambitious projects, was confirmed dead.

According to Mark Gurman, Apple has abandoned the project to develop and produce its own displays. Journalist Bloomberg mentioned that the cost and complexity of these efforts were too high, so the tech company gave up. According to sources, the decision to end this initiative was made around the same time as the cancellation of the Apple Car.

Details about the screens produced by Apple leaked in 2018, when it was reported that the company was experimenting with the technology. initiative T159as it was known within the country, started seven years ago in the hardware department and later passed into the hands of Wei Chen, Apple’s vice president of display technologies.

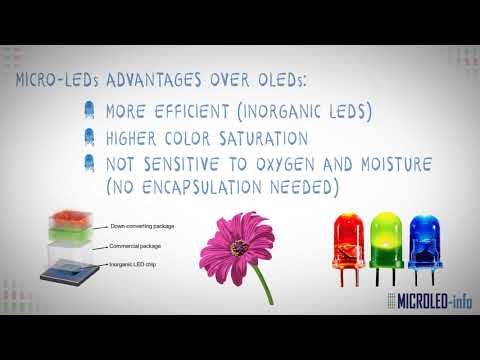

The project sought have more control over the design and capabilities of your products, similar to what we’ve seen with Apple Silicon processors. Cupertino residents considered microLED technology that offered benefits such as increased brightness and wide viewing angles.. Some employees then reported that the contents of these screens “appeared to be painted on glass.”

To implement Apple built a plant in Santa Clara test the production of microLED panels that will be integrated into the Apple Watch and then appear in the iPhone. Unfortunately, this project turned out to be more complicated than Cupertino expected.

Why did Apple cancel production of microLED displays?

Gurman notes that the main obstacle for microLED displays is that They could not be produced in large quantities.. The goal of the project was to integrate branded panels into the 2020 Apple Watch, although the pandemic and other internal problems ultimately delayed implementation until 2025. Apple didn’t have the infrastructure to do this.therefore he signed agreements with third parties.

Making a microLED panel is not an easy task. and includes two stages. In the first case, millions of microscopic LEDs are created that will represent colored pixels. This is done on the wafer through a process known as epitaxial growth, which creates thin layers of semiconductor material with a crystalline structure.

The second stage requires transfer each LED to a plane and make connections that will allow it to light up. Each LED is equipped with a thin film transistor that controls its brightness and color. This step, known as Pick-And-Place, is the most complex of the entire production and requires a company with advanced technology to complete it.

The complexity and cost of producing microLED displays may have been a determining factor in the project’s cancellation. Report Bloomberg mentions that Apple will lay off dozens of employees in Asia and the US, and one of its partners announced that it would close one of its screen factories. Those from Cupertino They will choose OLED screens produced by LG, Samsung and other suppliers.

Source: Hiper Textual

I’m Ben Stock, a highly experienced and passionate journalist with a career in the news industry spanning more than 10 years. I specialize in writing content for websites, including researching and interviewing sources to produce engaging articles. My current role is as an author at Gadget Onus, where I mainly cover the mobile section.