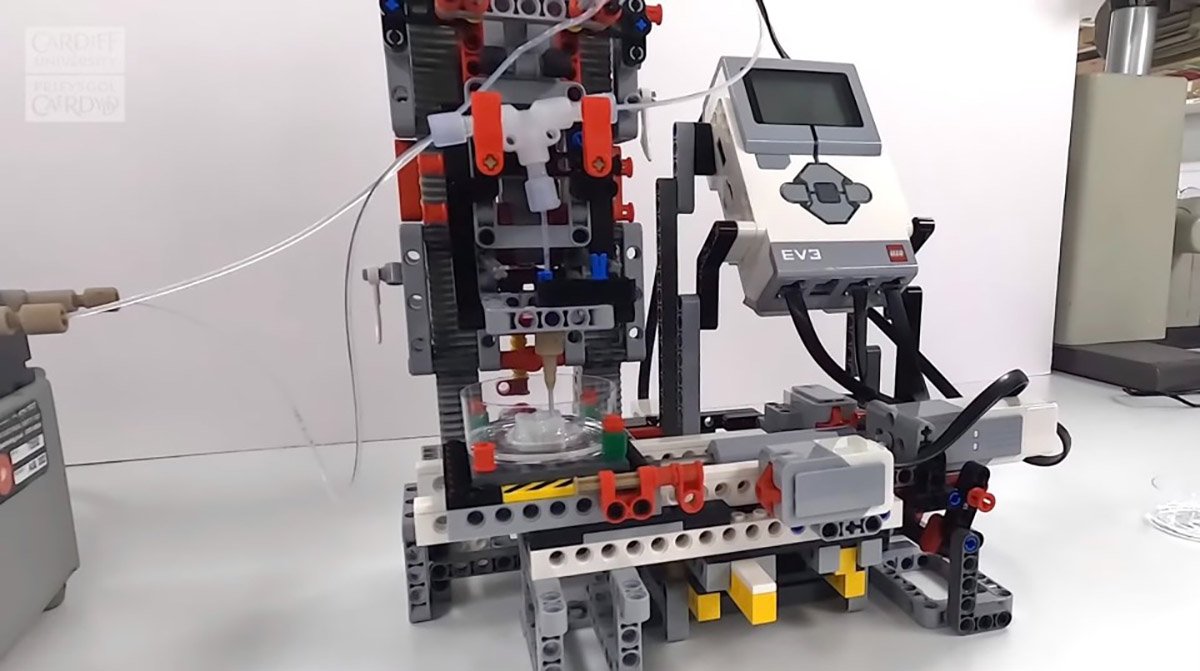

Researchers at Cardiff University in the UK have made a discovery that could revolutionize human skin bioprinting technology. A very useful 3D bioprinter made of plastic bricks from a Lego toy. The innovation is available as open source at an affordable price for labs worldwide.

While 3D bioprinters of synthetic human tissues have been known since April 2021 as a possible solution to the challenge of sampling such cells, your price is still too high.

The equipment, estimated at “a few tens, even hundreds, thousands of pounds” in an article published in The Conversation by the Cardiff team, is becoming prohibitive for many researchers. The cost of the Lego device just £500 (just over R$3,000) to buildthey reassured that the researchers told the news site.

How does the Lego 3D human skin printer work?

3D bioprinting emerged to fill the shortage of human tissue samples that have always been inadequate for biological research, even if they were obtained through organ donations or taken during the surgical procedure. New technology uses “bioink” cartridgesA type of pasty hydrogel containing living cells to create customized tissues and organs for patients.

Made by professors at Cardiff University’s School of Pharmacy and Pharmaceutical Sciences, the device is described in the research as “a benchtop Lego 3D bioprinter for producing additive layers.” A 3D scaffold containing live human skin cells inside a hydrogel scaffold“.

A scaffold is a three-dimensional support structure used to support cell or tissue growth. in a controlled material similar to its natural environment. This biocompatible material is hydrogel, a polymer that can absorb large amounts of water and is ideal for creating implants and prosthetics.

What are the future applications of the Lego 3D bioprinter?

The Cardiff-based bioprinter does not merely aim to provide a low-cost, representative model of human skin. The idea is to also be able to use it to add diseased cells to the generated models, thereby examining possible interactions between these structures in human skin. This approach will allow analyzes the progression of skin diseases and develops potential treatments.

Instructions on how to build a Lego 3D printer and assemble it in any lab were detailed in an article published earlier this year in the journal Advanced Materials Technologies.

Source: Tec Mundo

I’m Blaine Morgan, an experienced journalist and writer with over 8 years of experience in the tech industry. My expertise lies in writing about technology news and trends, covering everything from cutting-edge gadgets to emerging software developments. I’ve written for several leading publications including Gadget Onus where I am an author.